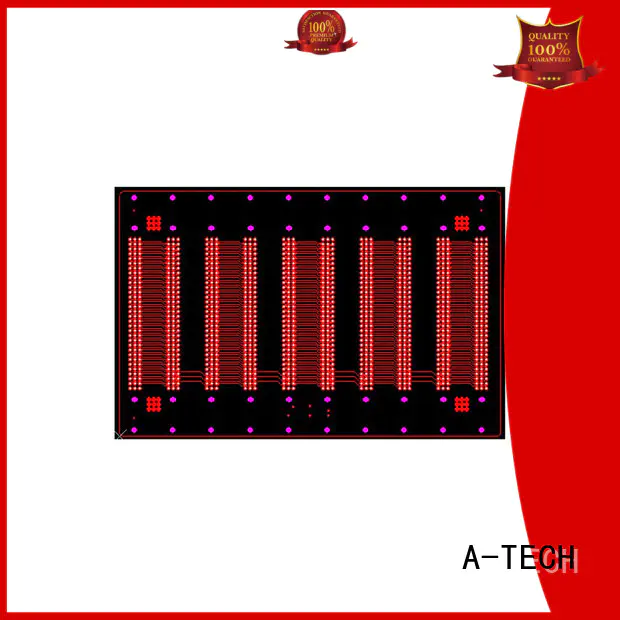

Press fit hole PCB, or called press fit pins PCB, they’re component holes with copper plated through and with tighter tolerance than standard PTH, the tolerance of standard PTH is +/-0.075mm(3mil), but the tolerance of press fit hole is normally +/-0.05mm(2mil).

Press fit holes are used as holes to fit the leads of connectors that will not be soldered but pressed into the holes. In order to accommodate lead and hole to tightly fit together, the tolerance on both are well defined, the typical tolerances for the press fit holes depends on the type of connector that is used and it’s the connector manufacturer who specifies this.

Press fit technology reduces PCB assembly time and effort considerably, and press fit pin eliminates the need for soldering, this cuts process time and cost, and boosts production output capacity. With no need to solder modules, engineers enjoy great flexibility in design. The module can easily be mounted on top or bottom of the PCB at no extra cost and effort.

A-TECH drill press fit holes with new drill bits and control specially in manufacturing process to ensure finished hole size within tolerance as specified.

Copyright © 2025 A-TECH CIRCUITS Co., Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.