Company Advantages1. A-TECH heavy copper pcb has been tested several times and meets regulatory requirements. These tests include dimensional stability, color fastness, wear or pilling, and the like.

2. This product is effective against pilling, which is a fiber ball produced on the surface of the bed supplies.

3. This product has strong color fastness. Using active printing process, it has bright color and strong fixation. A few washes won't cause its fading or pilling.

4. The product is user-friendly for it does not produce electromagnetic radiation which is harmful to people or produce thermal radiation and UV and infrared ray.

5. This product is lead and mercury-free, which contributes to environmental durability and the human body. Besides, users can recycle it to further reduce pollution.

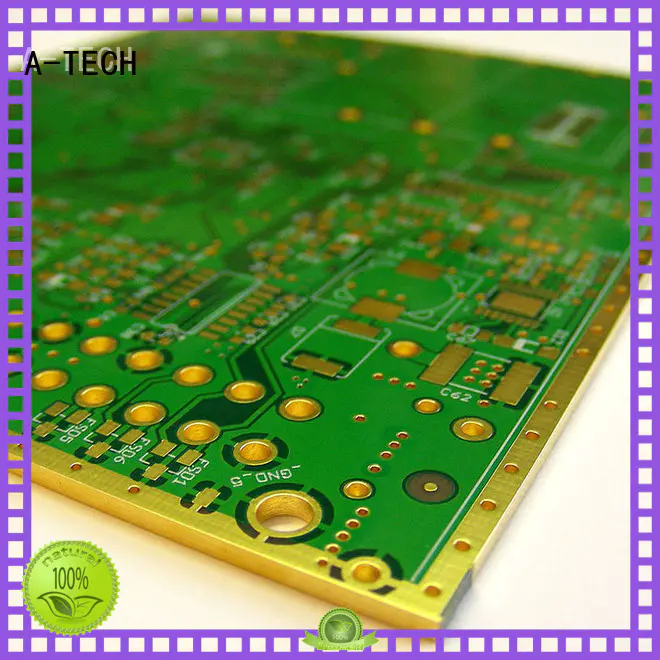

PCB edge plating, also called sideplating, it refers to copper plating that runs from top side to bottom side and runs along at least one of the perimeter edges. Portions of the printed circuit’s contour but also partial areas within the circuit board can be metalized.

In order to make PCB edges metalized, the printed circuit boards must be routed before through hole copper plated process, because the metallization of the PCB edges take place during this copper plating process. The ENIG (Immersion Gold) finish is preferred for PCB edges after copper plated.

PCB edge plating technology is used for several industries, especially in application that require better support function, such as:

● Edge connections and protection

● Edge soldering to improve fabrication

● Better support for connections such as boards that slide into housing connection

● Improving current-carrying capabilities for better EMC performance such as high frequency PCB

A-TECH has lots of manufacturing experience for PCB edge plating, and we’re able to control high quality for edge plating without burrs. Please try to contact our sales experts for any technical details.

Company Features1. A-TECH CIRCUITS Co., Ltd. is a specialist in both the design and manufacture of

hybrid pcb with access to and long-standing relationships with the most advanced brands in this industry.

2. A-TECH has strong unique technical strength to produce

edge plating pcb .

3. Our company bears social responsibilities. The energy we use at our various facilities is carefully controlled, and so are the emissions that we produce. Nothing that can be recycled is allowed to go to waste. Our passion and mission are to provide our customers with safety, quality, and assurance-today and in the future. Please contact us! To achieve sustainability, we will adopt the latest green manufacturing technology. We believe the application of the technology will improve sustainability and efficiency no matter in production methods or resource use. Customers' satisfaction rate remains a top priority in our operation. We will increase professional training themed on customer service, with an aim to strengthen employees' communicative skills and problem-solving ability.