The countersink is a kind of conical hole which drilled by special drill bits, it allows the tapered head of a screw to be inserted and screwed down in the hole to sit flush with the surface of the circuit board.

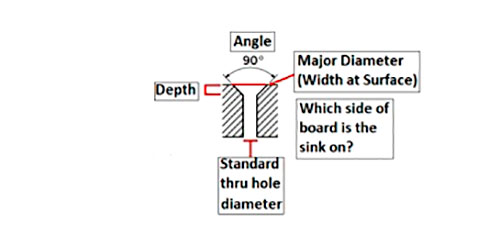

In order to ensure correct manufacturing for countersink design, PCB manufacturers require the details of the hole diameter or other specifications, the detailed information as below is needed:

● Countersink is drilled on top or bottom side?

● Countersink is copper plated or non-plated?

● The angle of countersink

● The finished diameter of countersink at the surface

● The depth of countersink

● The finished diameter of the shaft of the countersink

Drill bit with different angles are the key tools to make countersink, the angles with 82 degree and 90 degree are usually used in many kinds of design, but other angles like 60 degree, 100 degree, 110 degree, 120 degree and so on are also possible based on demands.

A-TECH is capable of building different types of countersink with different diameters and angles, and no matter copper plated or non-plated, welcome to send inquiry if you have related demands.

Copyright © 2025 A-TECH CIRCUITS Co., Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.