Company Advantages1. A-TECH castellated holes pcb is carefully tested for the optimum quality including lifetime tests when it is wire bonded to ensure that it has stable characteristics. With a compact design, it is space-saving

2. We are able to provide complete service system from pre sales to after sales. It is lead-free and environmental-friendly and has passed SGS test

3. The product is highly automatic. It will automatically switch on when low water level, and switch off when high water level. It is widely used in different electronics industries, such as telecommunication and consumer electronics

4. The product is valued for its wear resistance. It has been coated with a special layer to withstand numerous times of mechanical force. Its robust structure allows it to be used in harsh environments

5. The product features high energy density when compared to other batteries. It has a high power capacity without being too bulky. Its solder mask can be offered with green, blue, white, black, yellow, and red colors

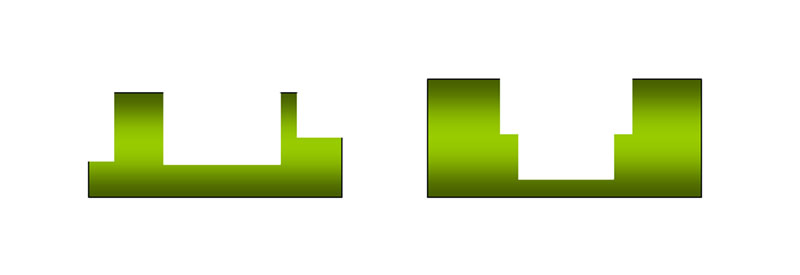

Depth control routing(milling) is also known as Z-axis milling or level milling, it refers to partial routing in printed circuit board manufacturing with a variable level elevation at the PCB edge or within PCB.

Control depth routing technology supports a high end market with the need for accuracy, miniaturization, process stability and the need for productivity, and depth routing option allows for very complex designs, bended boards and structures to be processed with fine precision.

Depth control routing technology have great advantages in PCB assembly as the special shape of depth routing.

● It can avoid cold soldering as siphonic effect use NPTH step stair slot

● Use the step stair in middle of PCB apply in special module application, and degrade the height of PCB assembly, achieve refinement and miniaturization

● Use the step stair of PCB edge make card slot is favor for PCB fixed and installation

● Use Special size NPTH step stair as resonant cavity of microwave signal, degrade signal loss and other special function.

A-TECH has manufacturing capability to build various types of depth routing with different size and depth, no matter on the PCB edge or within the PCB, and the precision tolerance can be controlled as +/-0.1mm(4mil).

Company Features1. A-TECH is good at producing high quality via in pad pcb . The basic requirement for A-TECH to maintain relies on the quality assurance of

blind vias pcb .

2. It turns out that putting

edge plating pcb in the first place takes effect for the improve of the company.

3. A-TECH CIRCUITS Co., Ltd. owns professional and experienced technical team to promise normal operation of production machines. We will replace the aging manufacturing equipment with newer and more energy-saving ones, aiming to promote more efficient production processes. For example, we have adopted water-saving equipment to help reasonably utilize water resource.