Company Advantages1. Three firmness levels remain optional in A-TECH micro vias pcb design. They are plush soft (soft), luxury firm (medium), and firm—with no difference in quality or cost.

2. The product stands out for its durability. It is able to withstand numerous times of repeatability and reproductivity without any failure.

3. The product has high hardness and toughness. The primary mechanical part is usually made of welded metal such as alloy and steel which have strong hardness.

4. This product is meant for a good night’s sleep, which means that one can sleep comfortably, without feeling any disturbances during movement in their sleep.

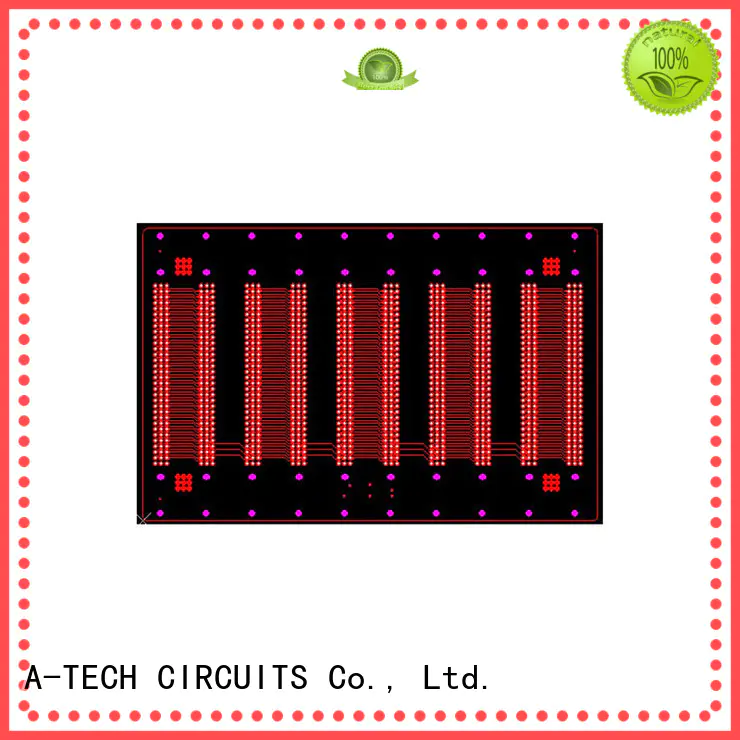

Press fit hole PCB, or called press fit pins PCB, they’re component holes with copper plated through and with tighter tolerance than standard PTH, the tolerance of standard PTH is +/-0.075mm(3mil), but the tolerance of press fit hole is normally +/-0.05mm(2mil).

Press fit holes are used as holes to fit the leads of connectors that will not be soldered but pressed into the holes. In order to accommodate lead and hole to tightly fit together, the tolerance on both are well defined, the typical tolerances for the press fit holes depends on the type of connector that is used and it’s the connector manufacturer who specifies this.

Press fit technology reduces PCB assembly time and effort considerably, and press fit pin eliminates the need for soldering, this cuts process time and cost, and boosts production output capacity. With no need to solder modules, engineers enjoy great flexibility in design. The module can easily be mounted on top or bottom of the PCB at no extra cost and effort.

A-TECH drill press fit holes with new drill bits and control specially in manufacturing process to ensure finished hole size within tolerance as specified.

Company Features1. Known as a strong competitor in manufacturing micro vias pcb , A-TECH CIRCUITS Co., Ltd. has a good business reputation in nearly every regions in domestic.

2. We have imported a series of advanced production units and facilities. They are highly integrated and run smoothly under the scientific management system, which can guarantee our constancy in product quality.

3. We have implemented a wide range of initiatives to realize sustainable development. For example, we fulfill our social responsibility through reduce CO2 emission. We will shift to a more environmentally friendly production approach. We handle all the scrap, waste gases, and wastewater strictly in line with relevant regulations. We have a clear business goal: to improve overall customer satisfaction. Instead of constantly expanding markets, we invest more in improving product quality and customer services to bring customers the product solutions to the utmost.