Company Advantages1. A-TECH

hybrid circuit manufacturers meets international furniture standards. It has passed ANSI/BIFMA X7.1 Standard for Formaldehyde and TVOC Emissions, ANSI/BIFMA e3 Furniture Sustainability Standard, etc.

2. The product is strongly resistant to rust. The materials of the frame adopt reinforced aluminum alloy whose surface has been treated with anodized finish.

3. The quality of

thick copper pcb meets up with all national standards.

4. Strengthening the service quality will be conducive to the development of A-TECH.

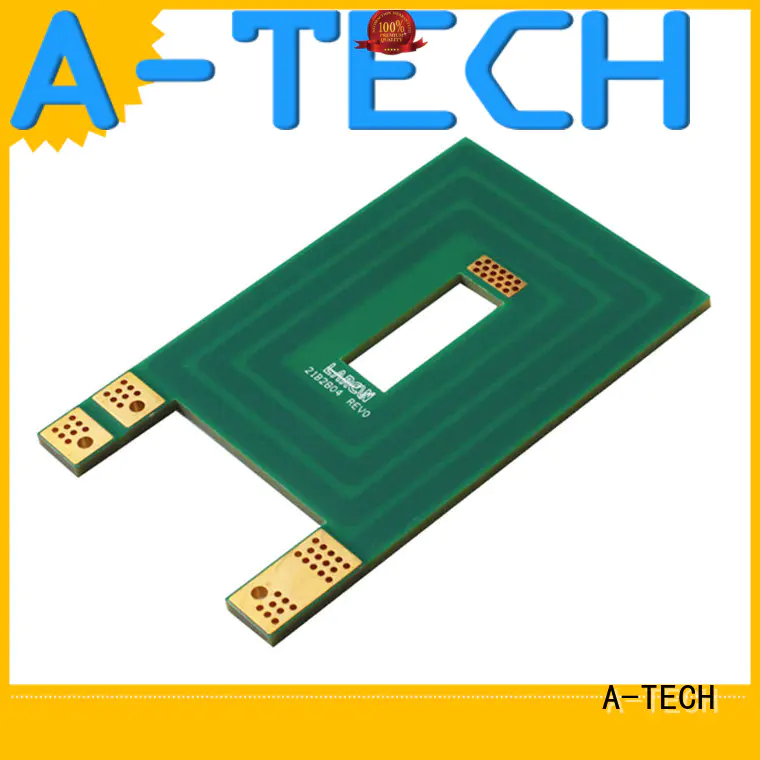

Thick copper PCB or called Heavy copper PCB, it refers to the printed circuit boards with copper thickness more than 3oz(ounce), they’re usually used for various electronic devices like central power system and power electronic devices which need high power or current through.

The applications of thick copper PCBs

● UPS systems

● Protection relays

● High power rectifiers

● Power grid switching systems

● Energy storage and power grid back up

● High power distribution

● Heat dissipation

● Planar transformers

● Power convertors

The advantages of thick copper PCB

● Better current carrying capacity

● Increased endurance to thermal strains

● Added copper plating in the heat vias

● Elimination of complex wired buss configurations

● Increased mechanical strength at connector sites

● Optimized use of exotic high temperature materials with lower probability of circuit failure

A-TECH have manufactured heavy copper PCBs more than ten years with very rich experience. Currently we’re capable of manufacturing thick copper PCB up to 12oz with our limit production capability.

Company Features1. A-TECH CIRCUITS Co., Ltd. has rich production experience in producing high quality and low cost thick copper pcb .

2. Solid technical foundation is the key for A-TECH CIRCUITS Co., Ltd. to greatly improve quality of

via in pad pcb .

3. We have made plans to participate actively in solving communities issues through our business-related, business-affected projects and activities. We will donate our products to the local people or the community to promote economic growth. Get info! In order to promote the happiness level of society, our company treats every employee equally without discrimination on ethnics or physical defects. Get info! We implement the Sustainability Policy. In addition to complying with existing environmental laws and regulations, we practice a forward-looking environmental policy that encourages responsible and prudent use of all resources throughout the manufacture. Get info! We establish an effective and efficient control system for waste and resources, with the aim of safeguarding the health and welfare of the community from any adverse environmental issues. All of the wastes will be treated by specific waste management facilities before discharge.