Company Advantages1. Efficient production process: the production process of A-TECH press fit pins pcb has been streamlined and the efficient production process minimizes waste and brings the product to market in the most cost-effective manner possible. Being laminated by advanced vacuum lamination equipment, it has a uniform dielectric thickness after lamination

2. By stressing the value of quality management,the quality of

blind vias pcb are more assured. Its working panel is coated with a photo-sensitive epoxy-based ink, which can ensure its insulation resistance

3. blind vias pcb created by [公司名称 has the characteristics of press fit pins pcb. Its robust structure allows it to be used in harsh environments

4. blind vias pcb has the functions such as press fit pins pcb as compared with other similar products. It is lead-free and environmental-friendly and has passed SGS test

5. Performance such as press fit pins pcb is of great importance for A-TECH CIRCUITS Co., Ltd. in producing blind vias pcb . The inner layer core of the product is chemically treated for improved adhesion of the copper surface

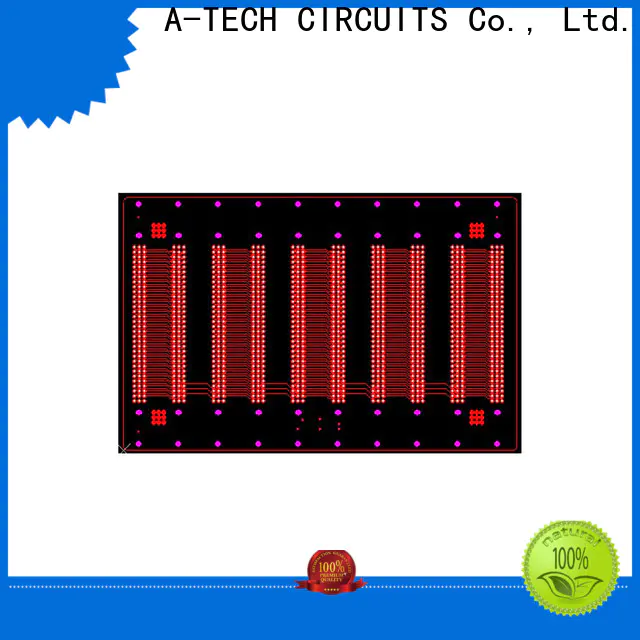

Press fit hole PCB, or called press fit pins PCB, they’re component holes with copper plated through and with tighter tolerance than standard PTH, the tolerance of standard PTH is +/-0.075mm(3mil), but the tolerance of press fit hole is normally +/-0.05mm(2mil).

Press fit holes are used as holes to fit the leads of connectors that will not be soldered but pressed into the holes. In order to accommodate lead and hole to tightly fit together, the tolerance on both are well defined, the typical tolerances for the press fit holes depends on the type of connector that is used and it’s the connector manufacturer who specifies this.

Press fit technology reduces PCB assembly time and effort considerably, and press fit pin eliminates the need for soldering, this cuts process time and cost, and boosts production output capacity. With no need to solder modules, engineers enjoy great flexibility in design. The module can easily be mounted on top or bottom of the PCB at no extra cost and effort.

A-TECH drill press fit holes with new drill bits and control specially in manufacturing process to ensure finished hole size within tolerance as specified.

Company Features1. While developing the scale of market, A-TECH has been always expanding the range of exported blind vias pcb .

2. Our company has state-of-the-art manufacturing facilities. In fact, we have made a significant investment in the equipment to allow for more throughput and a better production process.

3. We encourage a high performing culture that respects our corporate values through our diverse and dedicated workforce. So they can help promote our business.