why surface mount (smt) has become the preferred pcb assembly technique

After decades of steady development, it has become a compact, efficient and critical component of various machines, cars, computing terminals, plc and other electronic devices.

In addition, they have had an unparalleled impact on the introduction of new developments, technologies and inventions in the global electronics industry.

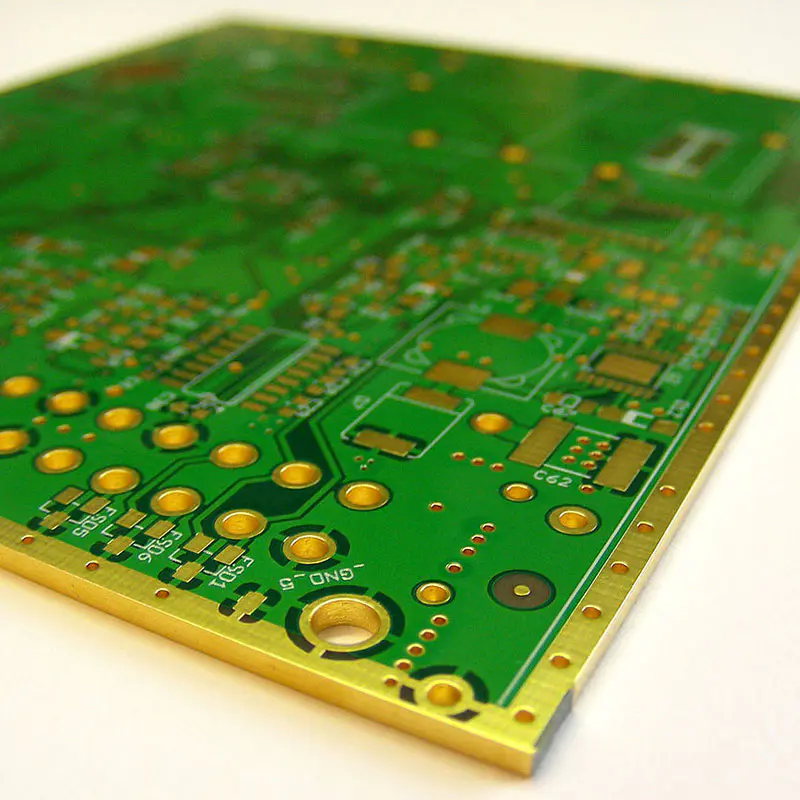

Their compact footprint and the high reliability of the individual electronic components of the electrical connection electronic design emphasize the complexity required to manufacture a high-quality pcb.

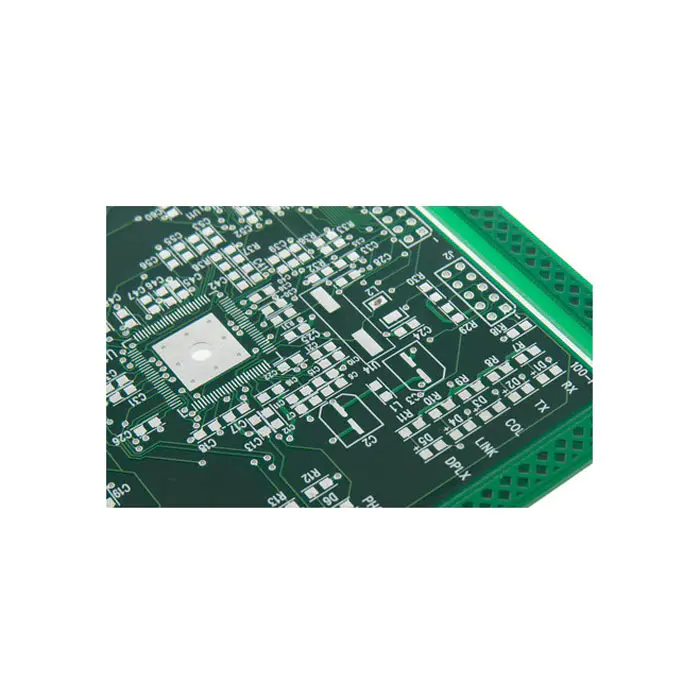

Today, the most popular PCB assembly technology is surface installation technology (SMT)

This is a huge improvement in the early assembly technology, suchhole assembly.

In many ways, SMT assembly is now considered the gold standard for PCB assembly technology.

SMT replaces other manufacturing processes and becomes the first choice for manufacturing pcb for reasons such as: time efficiency: point-before SMT assembly is widely used-to-

Point and pass-

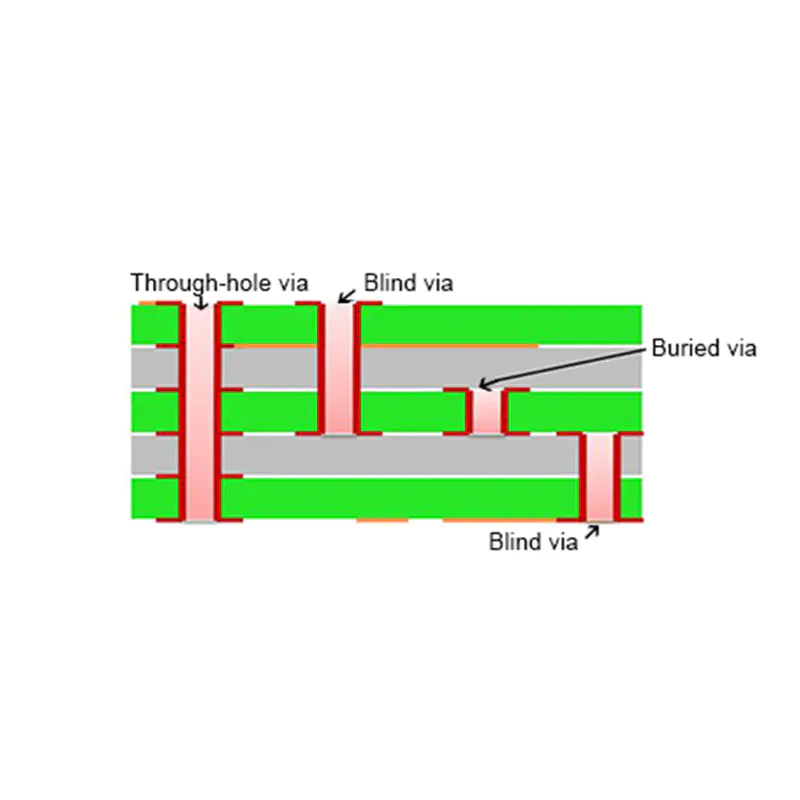

Hole Assembly is used;

However, these technologies consume a lot of time, because the fitters need to weld the pads to the frame of the PCB, and also need connecting wires, which requires not only more time to weld, it also changes the energy transmission mode of the entire PCB.

SMT by soldering the assembly to the PCB surface instead of passing through-

Hole connection point.

This simple innovation enables the pcb to be manufactured through automation, which is very time-saving.

Reduce assembly costs: traditional PCB assembly technology takes more time than automated SMT assembly.

Therefore, in the past, the production cost of pcb was higher than that of SMT assembly.

Also, for low

The number of pcb or prototype that design engineers usually need, the cost of producing a small amount of pcb using traditional assembly technology is very high.

But thanks to the ability to automate and arrange a variety of low production

At the same time, SMT assembly reduces production costs to an attractive price point.

Customers who care about the cost should always ensure that the PCB assembly service can automate SMT assembly.

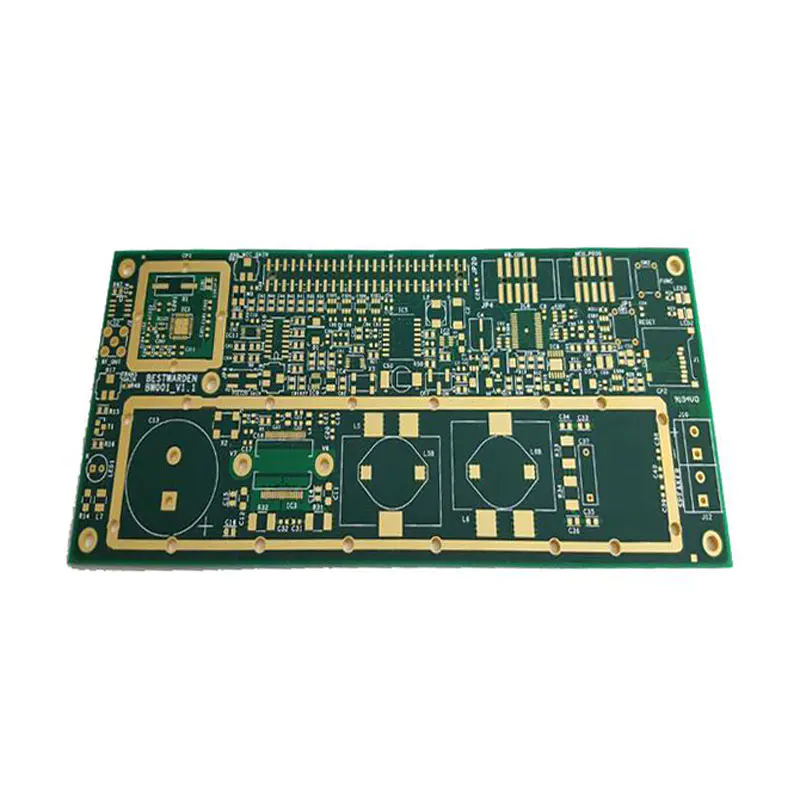

Enhanced availability: The PCB designed for SMT components uses smaller components than in the past, making the entire PCB more compact, stylish and energy efficient.

These advantages make the present

The Day PCB will be used for a wider range of devices, including handheld and laptop computers, smartphones or machines that require flat compact PCB control boards instead of large size boards.

SMT-for these reasons-

From electronic circuit design engineers to OEM mechanical designers, the pcb manufactured has been widely recognized throughout the industry.