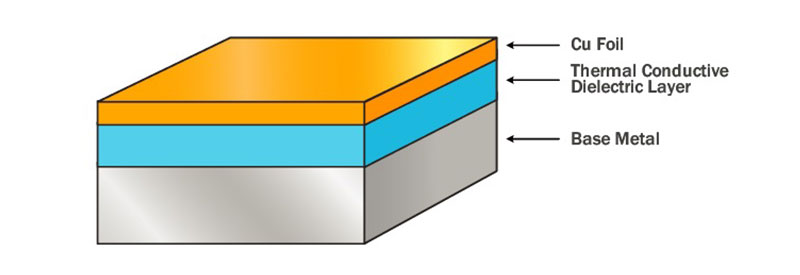

Aluminum PCB, or called metal core PCB and MCPCB, basically the Aluminum PCB is the most common metal used and the most popular type of metal core PCB, it uses a base metal material aluminum as the heat spreader portion of the printed circuit boards. Aluminum PCB has good thermal conductivity, electrical insulation and mechanical processing properties, metal core PCB is the most excellent and cheap cooling solutions.

The main difference between metal core PCB and conventional FR4 PCB is the thermal conductivity dielectric material and metal material backed, MCPCB are used instead of FR4 PCB because of their ability to efficiently dissipate heat away from the components, this is achieved by using a thermally conductive dielectric layer.

Basically LEDs are the largest users of these products, the other application areas for this technology include power converter, high current application, power circuit boards, automotive, RF application etc, they all take advantage of the benefits of this construction to make a quick and effective transfer of the heat produced.

The benefits of Aluminum PCB & Metal core PCB

● Thermal transfer exponentially more efficient than a conventional rigid FR4 PCB

● Heat dissipation is dramatically superior to standard FR4 constructions.

● Power densities can be increased while components are kept cool, increasing life and durability

● Dielectrics can be tailored to suit your thermal or insulation level requirements.

● Cooling properties allow devices to be driven harder or de-rated for lower cost components.

Aluminum PCB is one of the main circuit board product that A-TECH CIRCUITS manufactured, and the proportion is increased steadily due to our very competitive price and stable quality, with decade’s manufacturing experience, we have gained extensive knowledge in manufacturing various Aluminum PCBs to satisfy the requirements from worldwide customers.

| General specifications for Aluminum PCB/Metal core PCB in A-TECH | |

| Layer Count | 1-2 layer |

| Board thickness | 0.5-3.0mm |

| Copper thickness | 1-3oz |

| Thermal conductivity | 1.0-4.0W/m.K |

| Aluminum Type | 3003, 5052, 6061 |

| Breakdown voltage | 2-8KV |

| Soldermask | White, Black, Green, Blue |

| Profile | Routing, V-CUT, Punch |

| Raw material | BoYu, TOTKING, Polytronics, Bergquist etc. |

| Surface treatment | HASL, HAL(Lead.free), Immersion gold/Tin, OSP |

Copyright © 2025 A-TECH CIRCUITS Co., Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.