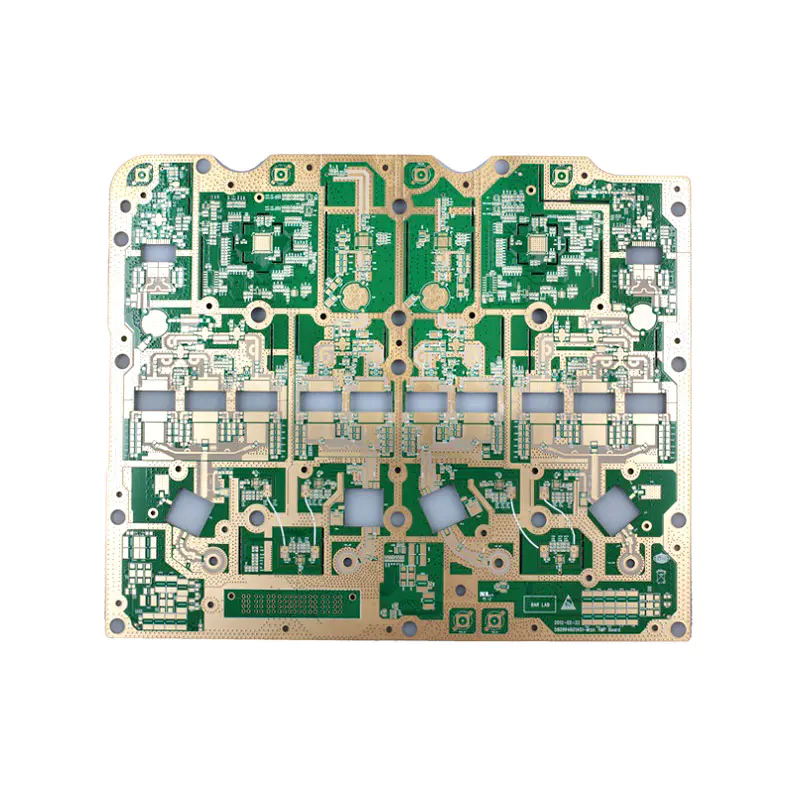

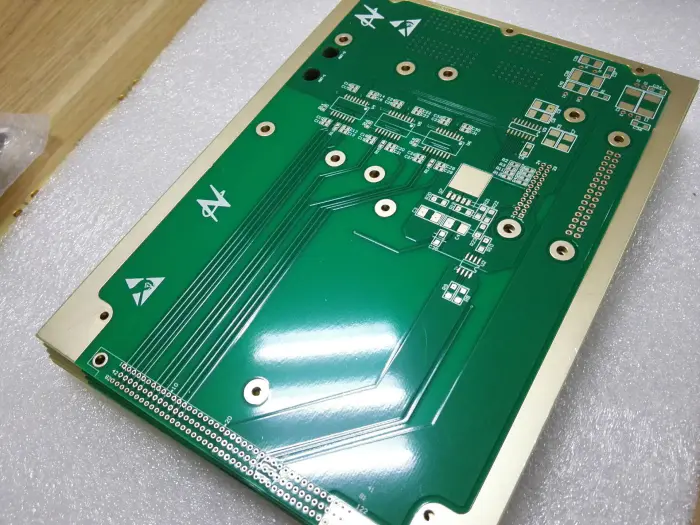

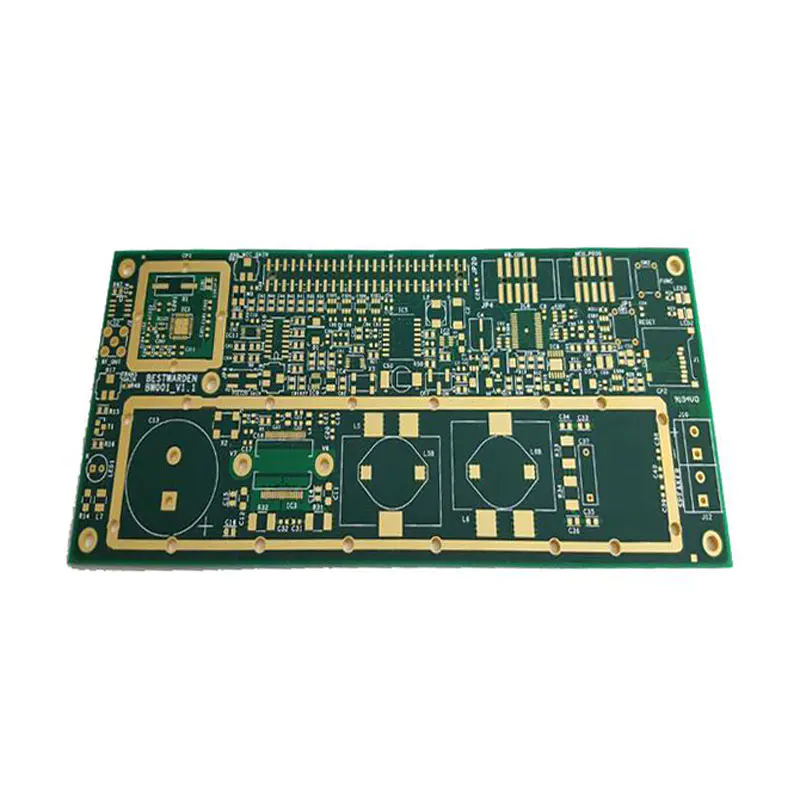

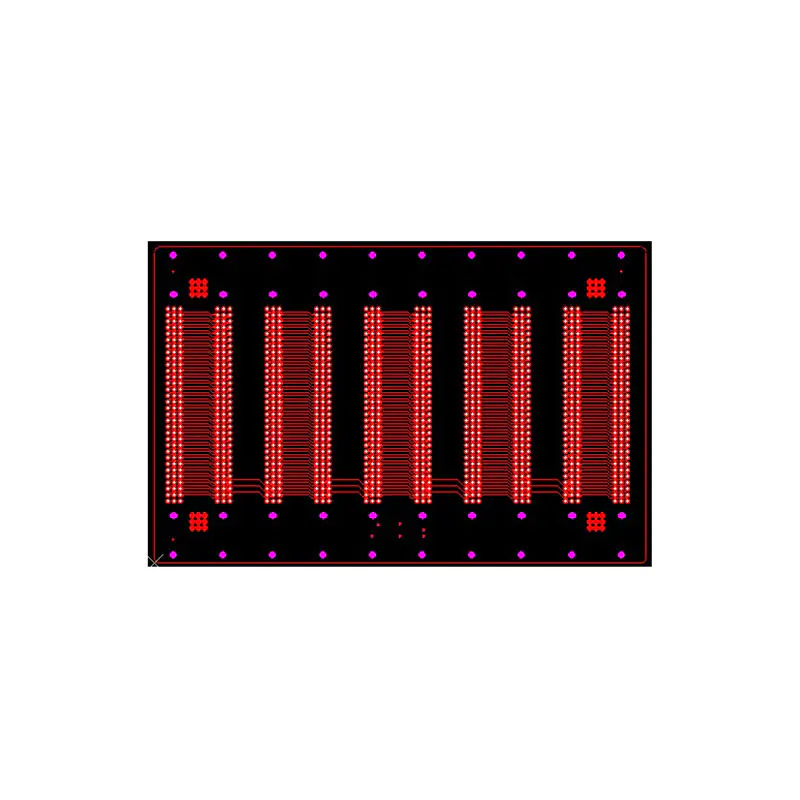

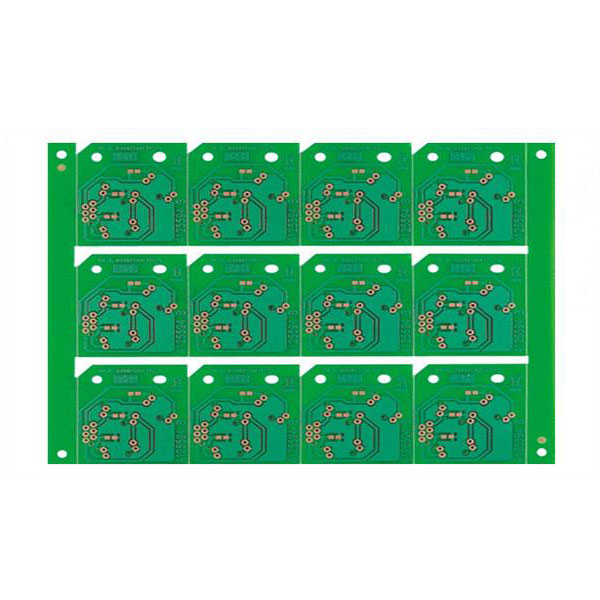

A-TECH CIRCUITS Co., Ltd. is a large integrated enterprise specialized in single-sided PCB research, exploitation, manufacture and production. A-TECH's main products include blind vias pcb series. The production of A-TECH single layer pcb involves several stages which include medical device design and prototyping, biomaterials and processing, machining, casting, and forming. Its solderable surface is protected from the oxidation. The product provides a sound seal system. The vertical seal of each panel is made of thick and tongue-type extruded aluminum laminated with a rubber seal. It is 100% produced in accordance with IPC-6012 & IPC-A-600F standards.

Bearing social responsibility, we have established our Corporate Sustainability Group in order to engage in sustainability management with ESG elements at the core.