What Are The Advantages Of Using A Printed Circuit Board

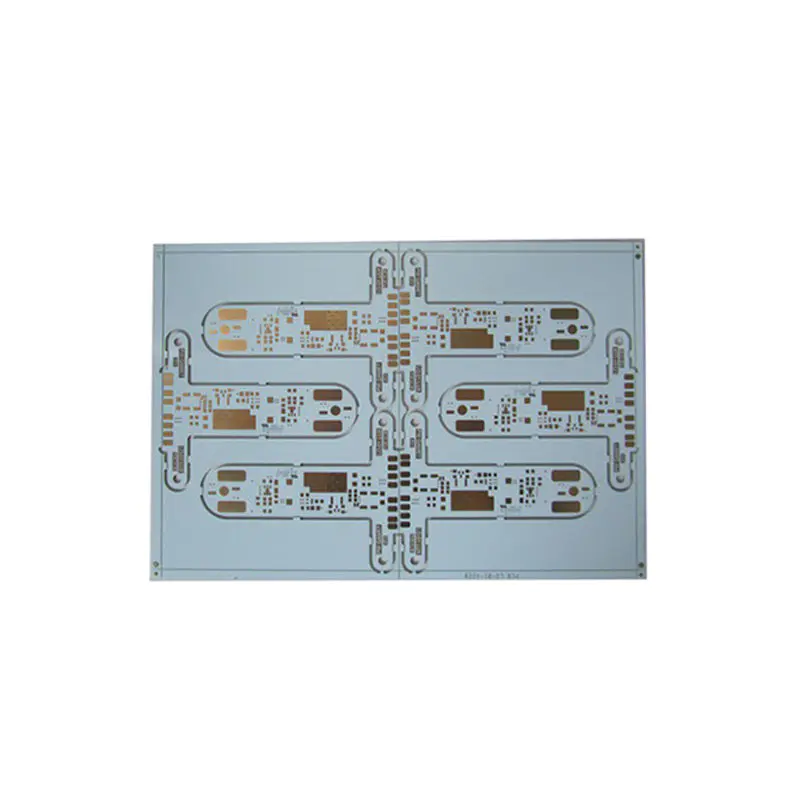

But it can be sensitive to contaminants, each in the air and on the board, and must be packaged as quickly as attainable. It is often used for membrane switches, EMI shielding, and aluminum wire bonding. We are the Printed Circuit Boards (PCB) producer Over 20 years experience, specialised in 1-26 layer pcb and excessive density interconnector (HDI) PCB. Our PCBs are used for auto business, excessive energy led, Office Appliance, electric toy, machinery, industrial lighting and so forth. The use of non-tin/lead coatings and floor finishes will enhance.

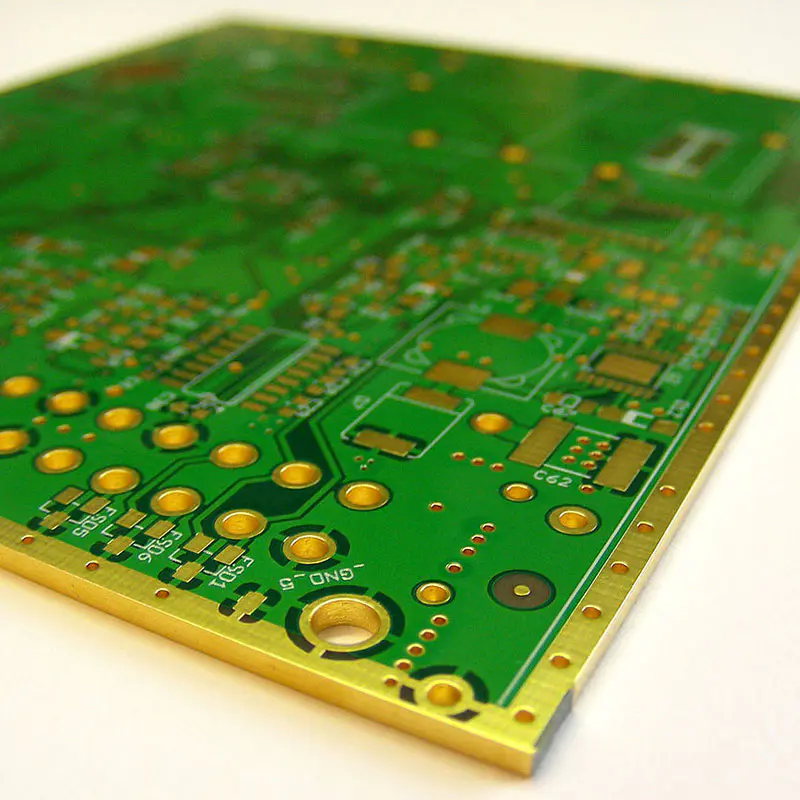

The ENIG (Electroless Nickel / Immersion Gold) approach consists creating a nickel deposit utilizing autocatalysis and then a deposit of a very thin layer of gold using immersion. The nickel protects the copper and creates the floor to which the elements are soldered. The nickel in this plating end supplies a barrier of protection between your board’s surface and the solder for elements, while the gold protects the nickel during long-term storage.

ENIG offers some nice advantages as being a lead-free resolution, having a protracted shelf life, and working nicely with via-hole parts. However, bear in mind that ENIG is dearer than other plating finishes, isn’t reworkable if mistakes are made, and may end up in sign losses. This plating uses a water-primarily based natural compound that bonds to the copper in your board to protect it throughout soldering. The benefit of OSP is its naturally lead-free nature, cost effectiveness, and simplicity of application by your producer.

On the one hand, this natural finish is able to stopping copper from oxidation, thermal shock and humidity. It gained widespread popularity because the RoHS and WEEE directive took impact, and is usually a good various to ENIG for fine pitch and flat pack coating. It's a steady finish with a average shelf-life (roughly 12 months) and relatively simple course of control.

Surface finishes corresponding to electroless nickel/immersion gold, OSP and immersion tin might be utilized. The present, frequent finishes like Electroless Nickel Immersion Gold (ENIG), Immersion Silver and organics like Organic Solderability Preservative (OSP) present much better planarity and smoothness for finer pitch devices. An example of such devices could be a Ball Grid Array (BGA), a Quad-Flat No-Leads package (QFN) or a Land Grid Array (LGA).

Your assembly house ought to be able to provide constant boards and supply PCB inspection to make sure no detail is left to chance. However, none of this issues if you don’t care for these PCBs accurately after they’re produced. Failing to handle and retailer your printed circuit boards may cause irreparable and expensive damage. HASL or sizzling air solder leveling is a sort of finish used on printed circuit boards (PCBs). OSP is brief for “natural solderability preservatives”, and it’s additionally referred to as anti-tarnish.

However, bear in mind that OSP has a short shelf life, you possibly can’t measure the thickness of it, and it’s not really helpful to be used with by way of-hole parts. At essentially the most primary level, a PCB floor finish is a plating or coating that is utilized to the exposed copper of a circuit board.