Company Advantages1. The design of A-TECH micro vias pcb is humanized and reasonable. To make it accommodate to different types of foods, the R&D team creates this product with a thermostat which allows adjusting the dehydrating temperature.

2. This product is somewhat chemical resistant. It has passed the chemical resistance testing for oils, acids, bleaches, tea, coffee, and so forth.

3. This product is durable. Paints, varnishes, coatings and other finishes are typically applied to its surface to improve appearance, and durability.

4. This product has the advantage of cost-effectiveness and has become a trend in this field.

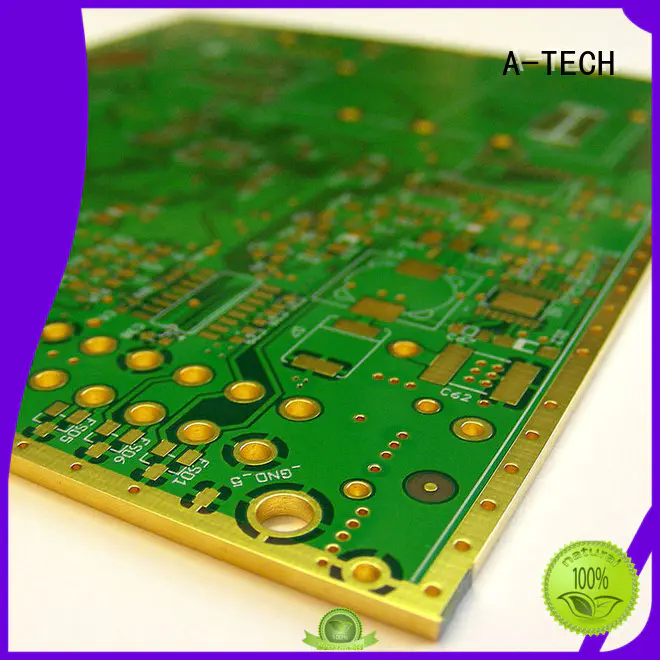

PCB edge plating, also called sideplating, it refers to copper plating that runs from top side to bottom side and runs along at least one of the perimeter edges. Portions of the printed circuit’s contour but also partial areas within the circuit board can be metalized.

In order to make PCB edges metalized, the printed circuit boards must be routed before through hole copper plated process, because the metallization of the PCB edges take place during this copper plating process. The ENIG (Immersion Gold) finish is preferred for PCB edges after copper plated.

PCB edge plating technology is used for several industries, especially in application that require better support function, such as:

● Edge connections and protection

● Edge soldering to improve fabrication

● Better support for connections such as boards that slide into housing connection

● Improving current-carrying capabilities for better EMC performance such as high frequency PCB

A-TECH has lots of manufacturing experience for PCB edge plating, and we’re able to control high quality for edge plating without burrs. Please try to contact our sales experts for any technical details.

Company Features1. A-TECH has become a top leading

via in pad pcb manufacturer.

2. A-TECH CIRCUITS Co., Ltd. has successfully got several patents for technology.

3. We endeavor to play an active role in reducing the negative impact on the environment. During production, we encourage less energy consumption and less pollution relying on newly introduced high-efficient manufacturing machines. Our company values are "passion, responsibility, innovation, determination, and excellence." By living up to these values, and bringing them into our day-to-day work, we achieve our ultimate aim of satisfying our customers. Trustworthy, Heartwarming, Energetic! is the motto that was born from our efforts to determine what makes us special. We will continue to keep these words firmly placed in our hearts. Sustainability is a crucial part of our company strategy. We focus on the systematic reduction of energy consumption and the technical optimization of manufacturing methods.