Osp Pcb,osp Board,pcb Osp

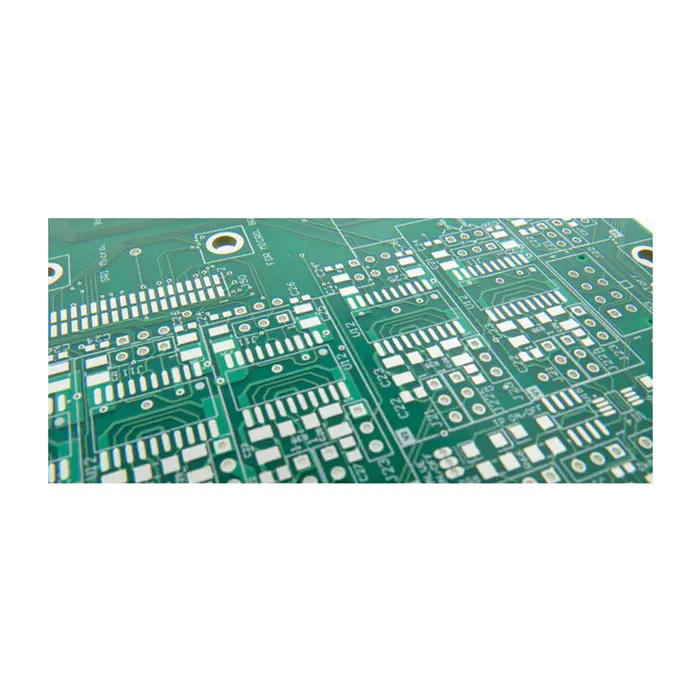

The solder paste can be wiped with seventy five% alcohol on non-woven material and dried with air gun. High temperature roasting can easily trigger OSP discoloration and deterioration. When transporting and storing PCB with OSP, separate paper ought to be used between PCB boards with OSP to forestall friction injury to OSP floor. Another choice, albeit dearer than Pb-free HAL, is ENIG (electroless nickel/immersion gold). This floor, like OSP, renders the pads very flat and presents the extra benefit of longer shelf life and the flexibility to wire bond.

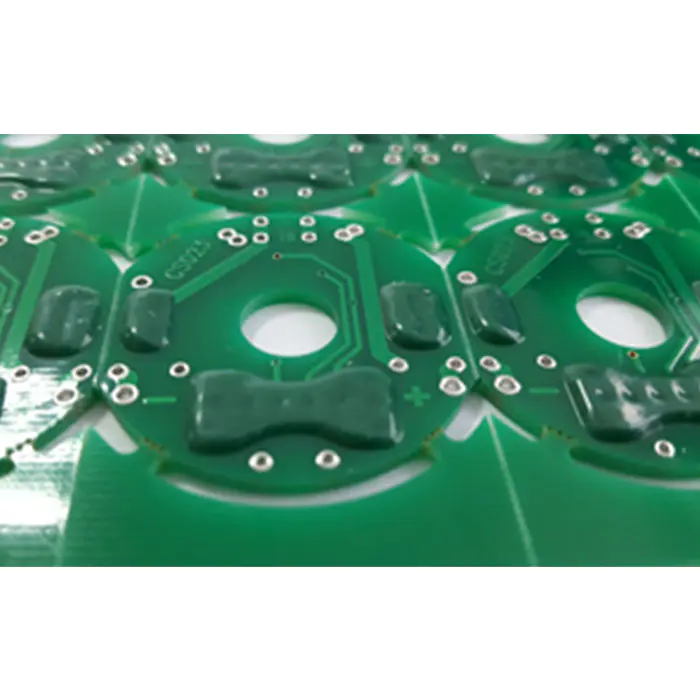

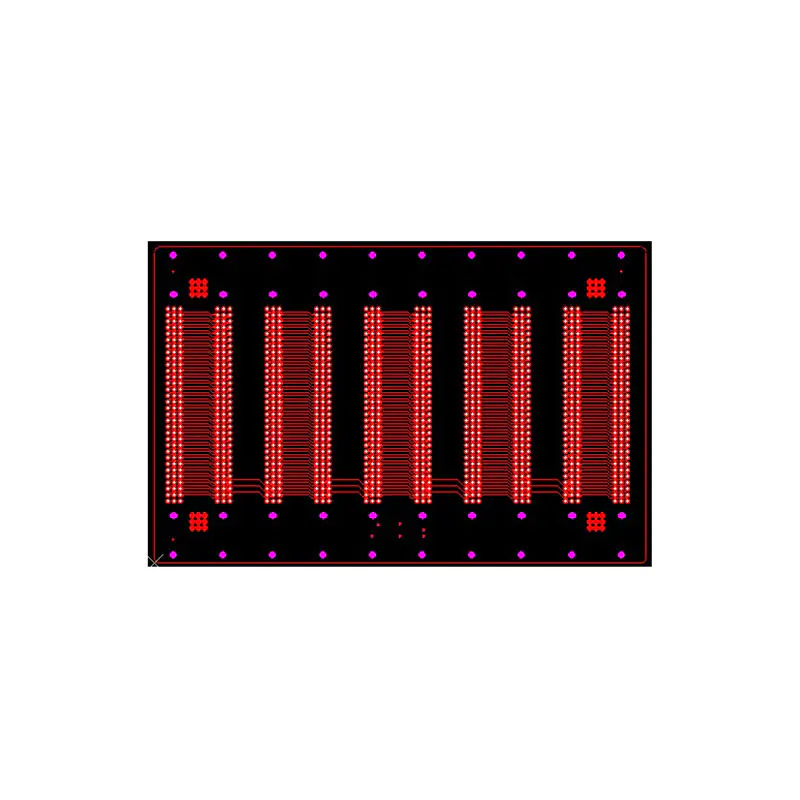

Microwave requirements might result in a low dielectric fixed and dissipation factor resin. 7.A sample if out there for higher sourcing eight.CAD files for enclosure manufacturing if required 9.A complete wiring and assembly drawing displaying any special meeting instructions if required. We can supply One-cease service for led mild, and focus on top quality led pcb and led controller board. We can design led circuit Board, led controller Board, firmware, iSO/Android APP, housing, bundle. San Francisco Circuits makes a speciality of helping you choose the right PCB floor end.

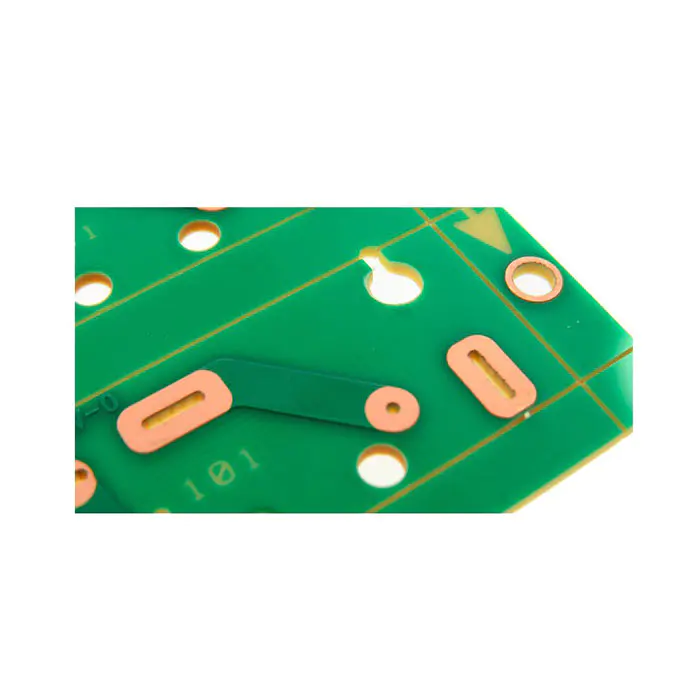

You have lots of components to think about like cost, utility environment, lead/lead free necessities, shelf life, and a lot extra! Let us fear about those things and give you the proper PCB surface end. The manufacturing course of for OSP is straightforward as seen in the picture above. “Clean” is the starting point with cleaning off organic contaminants corresponding to oil or fingerprints, to not get the copper foil surface contaminated before utility. For the best results and performance, the cleansing process should be checked as typically as potential.

Like the ENIG, this end materials is made of a layer of nickel coated by a layer of gold. The gold layer is tough gold, nonetheless, to protect the nickel in excessive-wear environments (such as keypads). Hard gold finishes also have a yr-lengthy shelf life, however they’re far more costly to fabricate. This tends to be specific downside when the gold plating process just isn't nicely managed.

If it doesn't preserve the standards for cleanliness the performance of the applying might be negatively affected. As with all of the floor finishes we’ve compared up to now, there are a number of benefits and drawbacks. Immersion Tin has been primarily used as a substitute for a lead-based mostly floor end.

This means, over time, diffusion of one metallic into the other will occur. It directly impacts the shelf life of the Immersion Tin deposit and finally the efficiency of the ? The thickness of the hard gold floor end will range depending on the functions. When onerous gold is used for compliance in navy purposes, the minimal thickness shall be micro inch.

Be certain to verify that yours does as properly and take advantage of it. Therefore, there's a need within the artwork for improvements to strategies of manufacturing PCB assemblies and particularly to the removal of OSP layers from conducive pads prior to reflow soldering processes. When PCB printed solder paste just isn't adequate, as OSP protecting movie is easily eroded by organic solvent, all OSP PCB boards cannot be soaked or cleaned with excessive volatile solvent.

Mechanical design elements would lead one to select rigid, flex, or bend-flex. Operating temperature would dictate when you required commonplace FR4, a high Tg version, a polyimide, PTFE, or ceramic.

OSP is an organic film chemically grown on a clear naked copper surface. Protecting the floor from further rusting (oxidation or vulcanization, and so on.) in normal conditions. An HASL surface end is probably essentially the most commonly used end in the whole business. It can simply solder to other surfaces, making it essentially the most versatile option available.

It can be used for its very flat and smooth end making it ideal for fine geometries and fantastic pitch surface mount components. Immersion Tin has its advantages, however there are a few disadvantages to using this surface end. As you could know, Copper and Tin have a strong affinity for one another.

Building a brand as A-TECH from the very start is simple so long as you keep 'the three C's' in mind: clarity, consistency and constancy.

What are you waiting for? Get out there and buy some of the most effective at A-TECH PCB .

The pcb suppliers in China-type pcb supplier is poised to lead the pcb manufacturer in China market.

People are more likely to listen to an expert than just anyone off the street. So, while pack mentality is important, having a relevant expert speak to the effectiveness of a brand's product as A-TECH is essential to converting new consumers as well.