O S.p. Finish

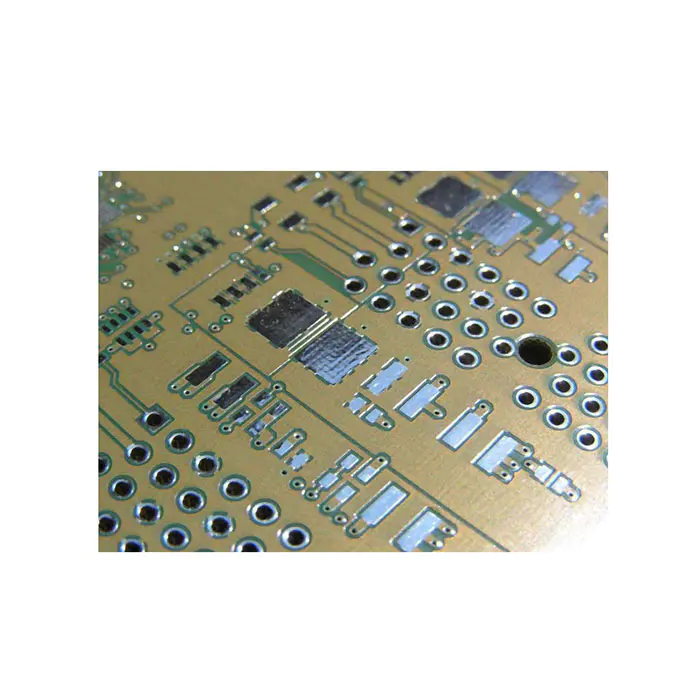

Assemblers favor to work with metal finishes which might be extra versatile and endure more warmth cycles. It also causes main issues at ICT with the mattress of nails fixture contact.

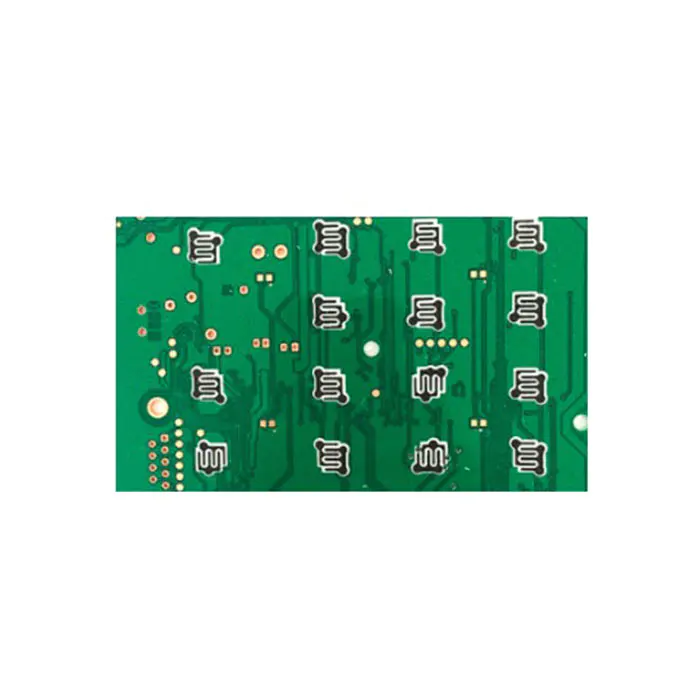

More aggressive probing is required to break through the OSP layer which could potentially even result in injury and piercing of the PCB test through or test factors. OSP PCB Board ManufacturingOSP, the complete name is Organic Solderability Preservative, it’s additionally referred to as preflux. OSP is a type of floor finish on bare printed circuit board that protect the copper floor from oxidation by making use of a very skinny protective layer of fabric over the exposed copper usually using a conveyorized course of. It’s a sort of surface know-how in PCB fabrication that meets RoHS necessities, and it could be the alternative solution for the surface finish of HAL(Lead-free). Finally, while not a finish in the typical understanding of the word, Hard Gold, or Electrolytic Gold end is often used for specific, non-soldering needs.

For PCB assembly, it has superior capabilities over conventional HASL with regard to coplanarity, solderability but requires vital course of modifications with the type of flux and number of warmth cycles. Careful dealing with is required as acidic fingerprints degrade the OSP and leave the copper susceptible to oxidisation.

Inevitably, tighter design standards, advancing technologies, and/or environmental legislation will pressure the substitute of HASL. There are lead free alloys which may substitute the conventional 63Sn / 37Pb solder on this course of, however there are still functionality limitations that exist inside this course of. OSP is designed to produce a skinny, uniform, protecting layer on the copper floor of the PCB’s. This coating protects the circuitry from oxidisation throughout storage and meeting operations. It has been round for quite some time but is simply recently gaining reputation with the search for lead free techniques and nice pitch solutions.

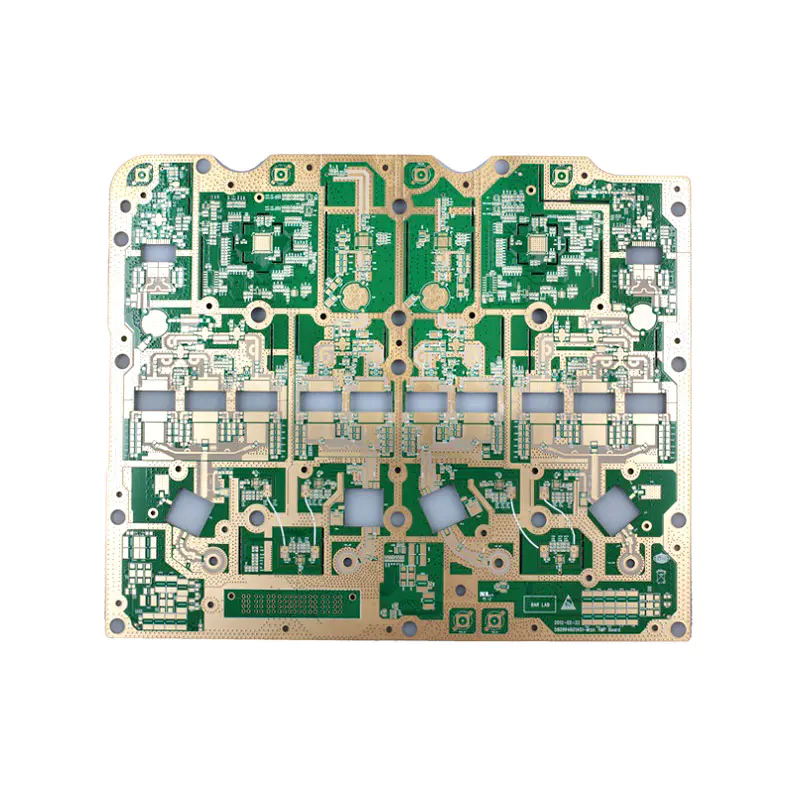

Instead of offering a good soldering point, Hard Gold is a mechanical barrier to protect the copper from corrosion and damage when being used to make contacts similar to gold fingers. This finish is extraordinarily expensive, being made from almost pure gold, and requires special design consideration to provide the connector points for the electroplating course of. Finishes are typically the final step of the manufacturing course of for PCBs before they’re cleaned and prepped for packaging. While no more important than different design choices in the course of of making a top quality circuit board, it isn't one thing that must be handled frivolously. A correct finish, in conjunction with other design issues, will make certain that the boards are of the very best high quality with the lowest wastage and rework ranges.