Max Interval Between Reflow For Osp Boards

And if you understand something about bridging, it’s that a brief circuit is shut behind, ready to damage your device. OSP is a transparent movie, it is not easy to measure its thickness, so the thickness isn't simple to control. The film thickness is just too thin to seek out the impact of not protecting the copper floor. Should even be regarded as an alternative choice to different lead-free floor finishes due to its relative flatness. A system based on claim 5, wherein outlets of the nozzles are positioned 10mm or less from the floor of the printed circuit board.

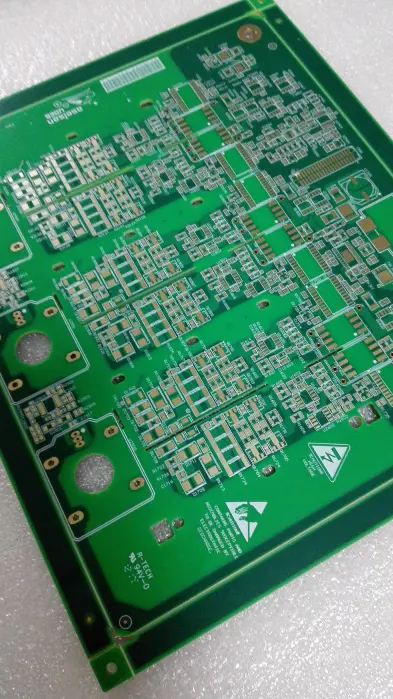

This makes it crucial to have a extremely qualified boardhouse to properly management and expedite the board packaging course of. This floor end can be subject to tarnishing, which is one thing to take into account. Diagram illustrating the difference between ENEPIG and different floor finishes.

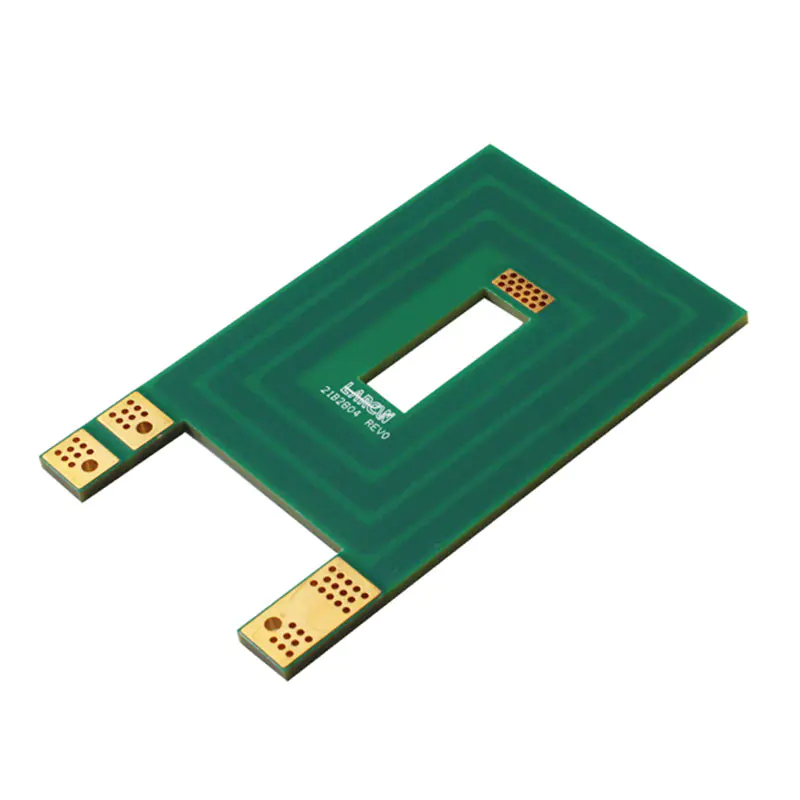

COM AC LED LIGHT ENGINE ,additionally referred to as AC MODULE and ac led module, combine the driving force parts on the board together with led,No requirement of AC-DC converter. By merely design and reduces elements rely,it provide a lower value for your new design or retrofit applications . Also the liberty of dimension and energy make your design flexibility and quick, that hold you ahead of competition on the market. These are the lead-free PCB surface finishes we now have obtainable on your PCB order.

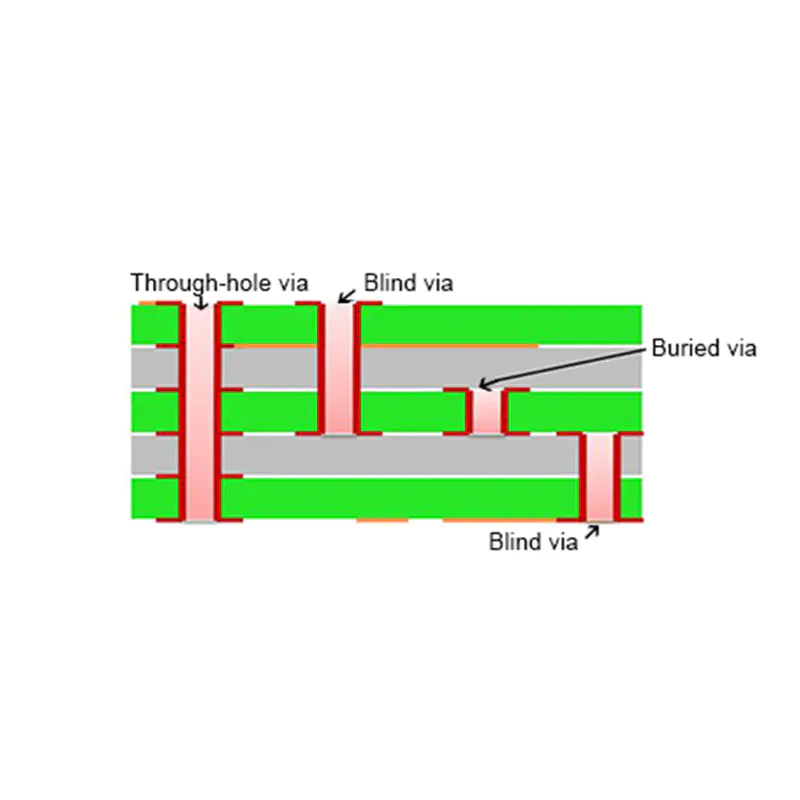

ENEPIG is a way derived from ENIG; the intermediate palladium layer prevents the nickel from oxidising earlier than immersion into the gold (which generates defects called black pad). ENIG is ideal for multilayer circuits that have finely spaced elements. To prevent the copper from oxidising and to guarantee correct element weldability, printed circuit surfaces must undergo a finishing step. This is an outline and some ideas to help you select the end most suited to your utility. Despite their almost invisible footprint, tin whiskers can create a bridge between the leads on digital units.

A system based on claim 5, whereby retailers of the nozzles are organized at an angle to the floor of the printed circuit board. A system based on claim 5, wherein shops of the nozzles are organized horizontally to the surface of the printed circuit board.

A system according to declare four, wherein the plasma generator is a plasma gun with a sequence of nozzles arranged to blanket the printed circuit board with the plasma environment. Figure 1 is a schematic diagram exhibiting a process for treating an OSP layer of a PCB in accordance with one embodiment of the current invention. When PCB circuit board changed from spout to OSP, the metal grid required re-opening.

On surface finishes with PF, copper discoloration was observed visually and micro-voiding at the pad interface was found on cross-sectioning. Based on the outcomes from the solder unfold take a look at, there was no vital enchancment noticed on the floor end with OSP versus PF, or surface finish with PF added as prime coat protection. In addition to ENIS, ENIG Hi-P, ENEPIG, and PF floor end, OSP and IAg were also evaluated. A whole of 9 teams of PCB floor end had been evaluated for solder unfold and voiding performance with assembled BGAs and QFNs.

There are some distinct advantages and drawbacks with the HASL surface finish. Here is a full table with a few of the pros and cons along with a few of the commonest makes use of for the Immersion Tin floor end. Tin Whiskering can be another downside to using Immersion Tin as a surface end.

The unfavorable results of tin whiskers growth are nicely described in trade related literature and subjects of several published papers. For the most effective results meeting (soldering) shall happen throughout 30 days. It has a decent shelf life of 6 to 12 months, however it can be delicate to contaminants found within the air and on some surfaces.