Company Advantages1. A-TECH enig pcb finish has undergone a strict production process including raw materials inspections and surface treatment to achieve a consistent chemical property, which can withstand changeable conditions in the bathroom. Thanks to the up-to-date vacuum DES line, it is manufactured with fine traces and high density

2. This garment feels comfortable, adjusts naturally to the activities of the wearer, and is consistent with the current fashions. It has low water absorptivity in the damp environment

3. Built with an eco-energy saver, it is energy keeping. It maintains efficient operation only consuming very little energy or power to operate. The inner layer core of the product is chemically treated for improved adhesion of the copper surface

4. This garment is of a good fit as its design is started from the human body measuring techniques and observation of the individual customers' figure formation. It has passed AOI which ensures there will be no errors or welding defects

5. The product is stain resistant. The product has been professionally burnished to create a smooth surface which is not easy to gather dust and dirt. It stands out for its impact endurance performance

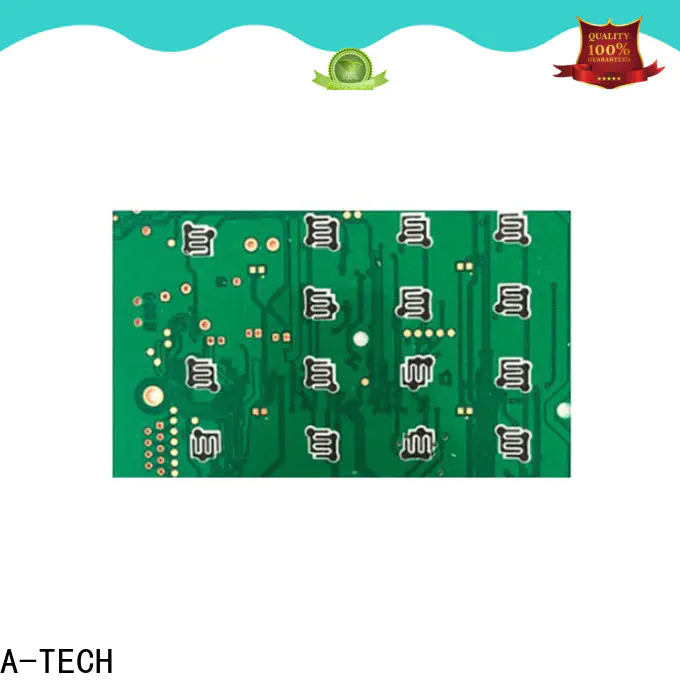

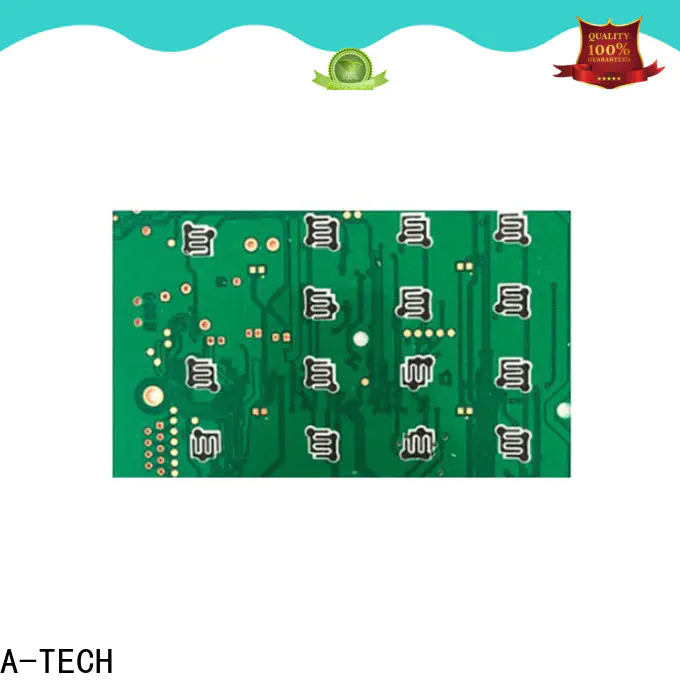

Carbon Ink is typically used to create a protective contact surface for switches, sometimes few copper elements or patterns of the PCB board are used for keyboard contacts, LCD contacts and jumpers etc, to do this it’s usable to print some conductive/resistive carbon ink over those copper part, which normally are SMD pads or fingers or other typical contact patterns.

Carbon Ink printing process is screen printing like silk screen process, the carbon ink is printed in the specified location of the PCB, after oven cured and tested, formed a carbon film which with certain resistance to instead of the original resistance components. The difference is that silkscreen is only played a welding role but carbon ink has conductive performance.

The typical thickness of carbon ink is 10-50um, because the carbon ink has good electrical conductivity, so the carbon printed on the finished PCB should have a certain gap to ensure that no short circuits, usually require the min 8mil gap for Hoz copper and min 12mil gap for 1-3oz copper, and the minimum carbon line width is 12mil.

A-TECH is a capable PCB manufacturer to offer Carbon ink process, we require the data files to clearly indicate on which side of the PCB carbon is to be applied and the carbon areas must be properly indicated on specific layers with proper file naming.

Company Features1. A-TECH CIRCUITS Co., Ltd. is a famous manufacturer of enig pcb finish with rich industry experience. Our

immersion silver pcb finish are made by our advanced technology.

2. A-TECH continuously improves its quality management system to achieve excellence, innovation, and customer satisfaction.

3. Guaranteeing the advanced technology is a very important step for realizing the quality of immersion tin pcb finish . In our way of working we change our behavior and implement, from complex to simple, activities to reduce our environmental impact and improve our social engagement.