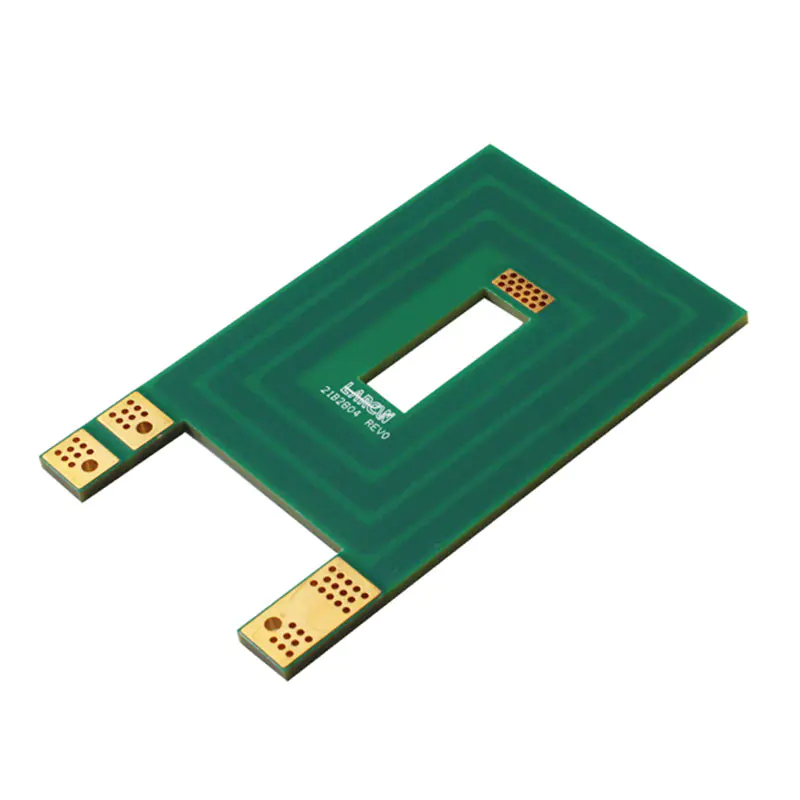

Gold Fingers

It uses a water-based organic compound that selectively bonds to copper and supplies an organometallic layer that protects the copper previous to soldering. It’s additionally extraordinarily green environmentally compared with the other common lead free finishes, which Suffer from both being extra poisonous or substantially higher energy consumption. It could be seen that OSP is increasingly popular within the trade due to its simple course of and low price. OSP is brief for 'natural solderability preservatives', and it is also known as anti-tarnish.

If you expect a high quantity of production this may not be a difficulty. And if you're utilizing massive batches of boards rapidly, you'll be able to avoid tarnishing. However, if your manufacturing volume isn’t excessive, it could be higher to decide on a coating like immersion silver.

During the soldering process, the silver layer dissolves into the solder joint, leaving a (6-12 µin) Tin/Lead/Silver alloy on the Copper, making very reliable solder joints for BGA packages. Another benefit to using Immersion Silver is the color distinction that allows easier inspection.

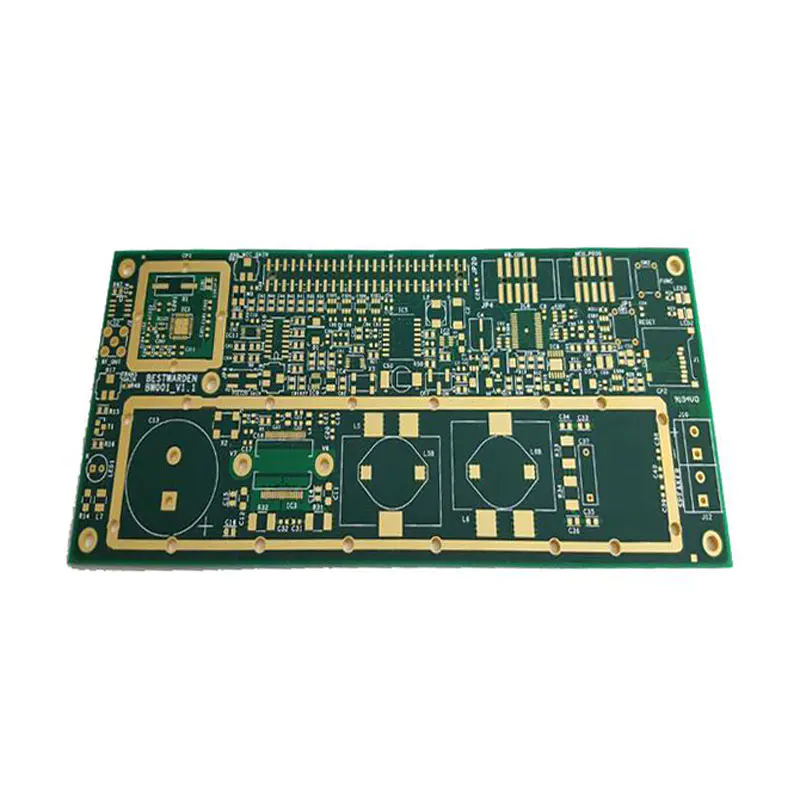

During the design part of a printed circuit board one of many selections that needs to be made is what floor finish to select. Unfortunately there's no one 'best' PCB floor end and all finishes have both good and unhealthy points. Selecting a floor finish is a matter of constructing a decision based mostly on trade-offs which might be most appropriate for the meant use. OSP, the complete name is Organic Solderability Preservative, it preserves the copper floor from oxidation by making use of a really thin protecting layer of material over the exposed copper usually using a conveyorized process.

Silver is suitable with most meeting processes, is price advantageous, and with its increased popularity, is turning into more generally available. When a design is finalized and a layer stack is defined, an outline file is enclosed that tells a PCB producer what sort of finishing is requested. This floor finish is in between the elements and the board’s copper. The sort of finishing is necessary and is set by the PCB utilization. There are a number of finishing strategies and the five most typical will be described here.

The EPAG (Electroless Palladium Autocatalytic Gold) PCB end and EPIG (Electoless Palladium Immersion Gold) PCB end are a direct palladium surface finish. This end is for any market that wants non-magnetic bonding ie army, aerospace and deep sea RF. The major disadvantage is that after the tin is deposited onto the copper it begins to tarnish. That signifies that if you want to keep away from decrease high quality solder joints, you have to do your soldering inside 30 days.

The process is easily controlled and is more economical than metallic finishes that present similar protection. The movie thickness is essentially self-limiting and is easily controlled through the working parameters. With the pending lead-free legislation impacting PCB manufacturing on a world scale, the immersion silver course of is rapidly gaining popularity because the lead-free floor finish of choice. While ENIG presently has a larger market share, over the past 12 months extra immersion silver process strains have been installed in PCB services than another finish. Immersion silver has a managed thickness of 5-12 micro inches and a shelf life of a minimum of 12 months.

On the one hand, this organic end is able to stopping copper from being oxide, thermal shock or moisture. On the opposite hand, it must be easily eliminated by flux in the later means of soldering in order that the uncovered clean copper can be jointed with melting solder in order that solder joints could be generated in extraordinarily quick time. used within the scorching air leveling course of additionally fails to satisfy the environmental protection requirements. With the official implementation of the European ively bonds to copper and protects the copper till soldering.

Some individuals do not consider that OSP is a good finish, even for single aspect reflow. This is the most effective floor finishing used right now as it permits a flat floor with excellent solderability regardless of the next cost. When applied the gold truly dissolves into the solder so that it gained’t tarnish or oxidize. It is a 2-layer course of by layering nickel on high of copper first than including a ending layer of gold. is an organic solderability protectant course of and offers a skinny, uniform, non-tacky film able to maintaining the solderability of the copper surface through a number of soldering thermal cycles.

Printed circuit boards, PCBs, could be produced from a wide range of substances. The most generally used in a form of glass fibre primarily based board generally known as FR4. This supplies an affordable diploma of stability beneath temperature variation and is doesn't breakdown badly, while not being excessively expensive.