Company Advantages1. The light-emitting diodes used in this A-TECH

impedance control pcb is an essential element, which is used as substitutes for mercury incandescent lamps. It gives strong light with high efficiency.

2. This product had the required breathability. The materials used have the ability to permit water vapor to pass through and to prevent the entry of water, thereby reducing the risk of foot odor.

3. The product has a smooth surface. In the polishing stage, the sand holes, air blisters, pocking mark, burrs, or black spots are all eliminated.

4. This product would be so soft and gentle on users' skin, providing a soft, breathable and cozy sleeping experience.

5. The product can make the production process flow more efficient. It greatly contributes to a reduction in the production schedule and costs.

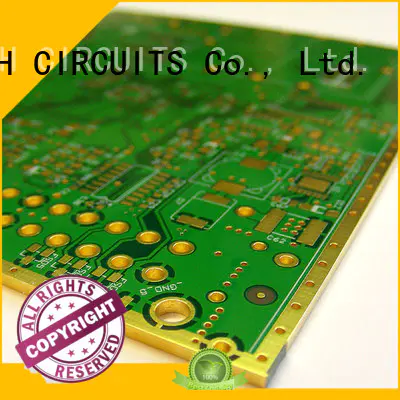

PCB edge plating, also called sideplating, it refers to copper plating that runs from top side to bottom side and runs along at least one of the perimeter edges. Portions of the printed circuit’s contour but also partial areas within the circuit board can be metalized.

In order to make PCB edges metalized, the printed circuit boards must be routed before through hole copper plated process, because the metallization of the PCB edges take place during this copper plating process. The ENIG (Immersion Gold) finish is preferred for PCB edges after copper plated.

PCB edge plating technology is used for several industries, especially in application that require better support function, such as:

● Edge connections and protection

● Edge soldering to improve fabrication

● Better support for connections such as boards that slide into housing connection

● Improving current-carrying capabilities for better EMC performance such as high frequency PCB

A-TECH has lots of manufacturing experience for PCB edge plating, and we’re able to control high quality for edge plating without burrs. Please try to contact our sales experts for any technical details.

Company Features1. Over the years, A-TECH CIRCUITS Co., Ltd. has been increasingly stronger and more well-known in the industry of impedance control pcb .

2. Skilled designers in A-TECH CIRCUITS Co., Ltd. will create product definitely catering to costumer's taste.

3. We insist on our managing principle of surviving based on quality and improving based on innovation. We will enhance learning about world-cutting-edge manufacturing techniques and keep our own way of innovation. Sustainability is vital for our business growth. We optimize the collection and recovery of waste so it can become a source of new resources to recycle and recover. We strive for results orientation. We consistently deliver required business results, meet deadlines and comply with quality, productivity and performance standards.