Electroless Nickel Immersion Gold

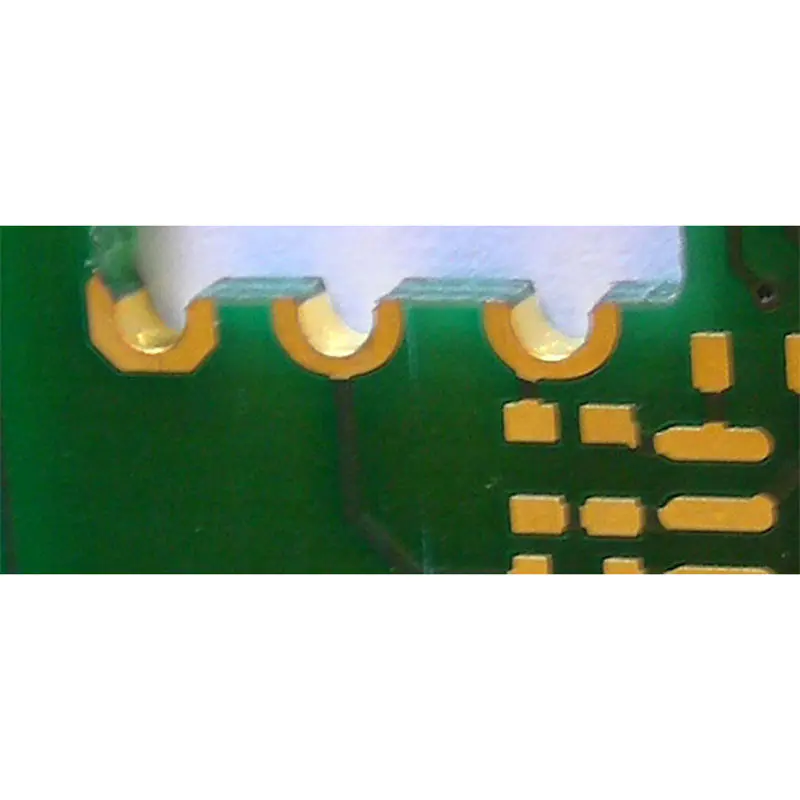

However, very little attention has been paid to the corrosion resistance of the lead-free PWB finishes as soon as they are field deployed. This is partly because of the fact that the normal board finish, HASL, has wonderful corrosion resistance because of its thick coating and inherent corrosion resistance.

In this work, the corrosion resistance of the lead-free PWB finishes has been evaluated utilizing a extremely accelerated blended flowing fuel test. Not surprisingly, currently used accelerated corrosion test situations have been proven to be insufficient to challenge merchandise in harsher environments. A comparability will be made between present testing requirements and our check conditions.

As little as 7 years in the past over 70% of electronics used SnPb sizzling air solder level (HASL) because the finish. The lost market share has been distributed among the many different finish choices. Two developments are answerable for this major business transition, the most obvious being the RoHS restriction of Pb. The other is the continual pattern towards placement of finer pitch components (making assembly with HASL more difficult). As the digital trade is transferring to steer-free PWB last finishes and excessive density circuit boards, the extensively used PWB end, SnPb HASL, has to be changed with a lead-free and coplanar PWB finish.

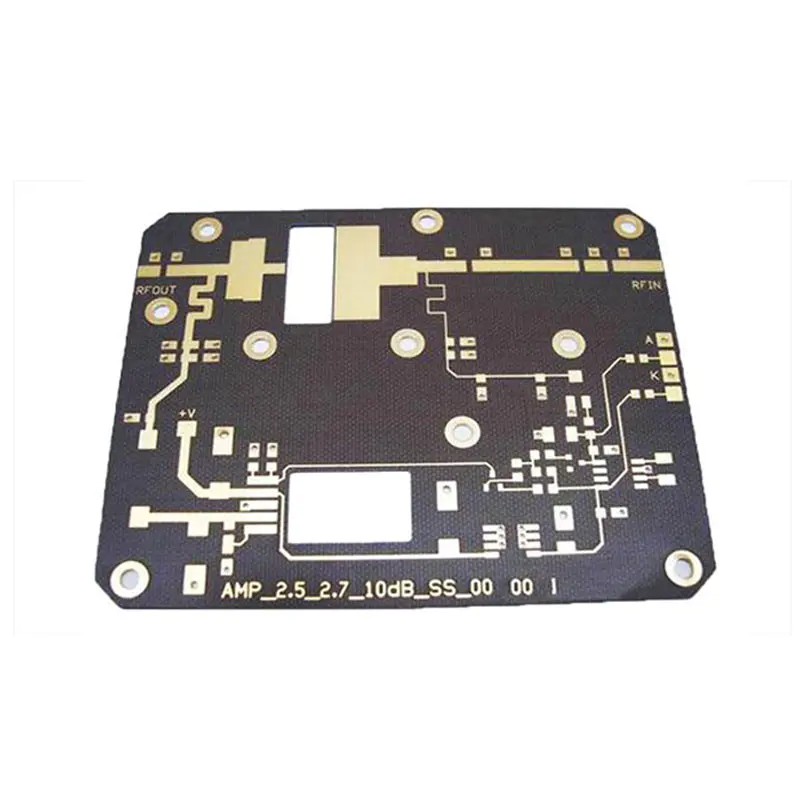

A range of finish types offers totally different levels of safety in opposition to deterioration. Various circuit board finishes are available, from options that are affordable and easy-to-apply to expensive or difficult-to-handle finishes used in only the most advanced purposes.

For extreme corrosion situations, several new failure modes associated with the lead-free PWB finishes might be reported and their relevance to subject deployed product shall be discussed. The influence of the corrosion on the long-term reliability of the electronic units will also be discussed. Every surface end has an Achilles Heel that affects fabrication, solderability, testability, reliability, or shelf life.

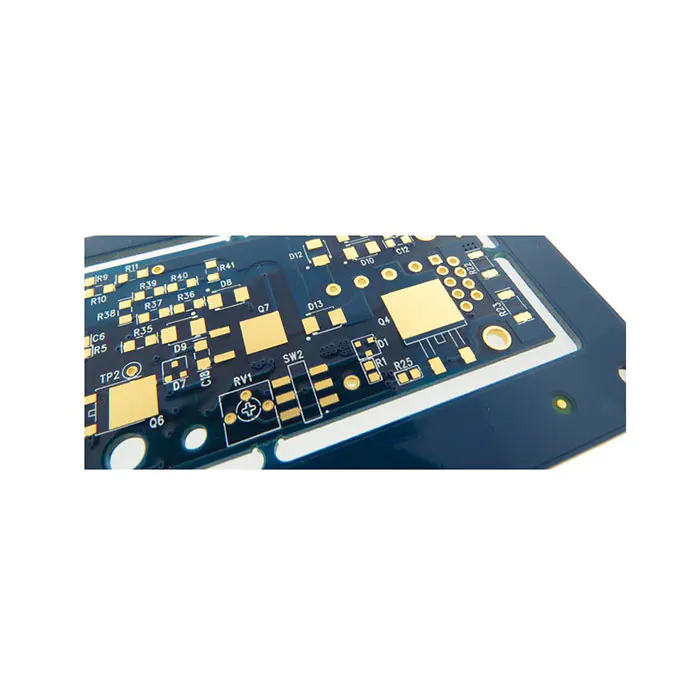

Surface end choice ought to be based mostly on the specific software and a comparability of the advantages and drawbacks. The floor of printed circuit boards (PCB) is manufactured from copper to make sure electrical currents move effectively. These metals require applicable protection from the elements to keep away from oxidation and different corrosion.

This transition has already occurred for many commercial products as of July, 2006. Long-time period, high reliability products corresponding to within the Telecom industry are still evaluating the reliability of these lead-free finishes. The popular choices for changing HASL are OSP, ImAg, ENIG, and ImSn. Among these lead-free finishes, ImAg and OSP are the preferred finishes for many applications, while ImSn and ENIG are used for area of interest purposes. Extensive testing and reliability assessments have been performed on the 4 lead-free PWB finishes.