Circuits Assembly Online Magazine

What makes the black pad defect so troubling is that it is invisible to the bare eye for the reason that gold covers the underlying downside. Furthermore, for numerous reasons it can occur on some areas of the board and never others.

Such tarnishing doesn't sometimes lead to failure, however, if the PCB is seen to the user the end result can be a poor perception of quality (for example the uncovered PCB on a hard drive). Poor cosmetics of the PCB can result in extra frequent alternative of PCBs in the field. Freed, 'Creep Corrosion over Gold, Palladium and Tin-Lead Electroplate,' 15th Annual Connectors and Interconnection Technology Symposium Proceedings, Philadelphia, PA, 1982, pp. .

Greg York has over thirty two years of service in Electronics business. York has put in over 600 Lead Free Lines in Europe with Solder and flux systems in addition to Technical Support on SMT strains and trouble capturing.

Mark has over 25 years' expertise in electronics fabrication, quality and reliability while working for IEC Electronics, GE, Motorola, ORS, and so on. He has most recently established IEC Electronics Analysis and Testing Laboratories (IATL), LLC in Albuquerque, NM for electronics and material evaluation testing within the navy, medical, and industrial industries. His space of expertise includes PCB, PCBA, parts, analytical and electrical evaluation methods. If you are seeing oxidation on the pads as they are obtained, that is actually not regular. Any oxidation from fabrication is eliminated by the prep line previous to the actual utility of the coating, so the oxidation you're seeing needed to happen later.

Most would argue that the incident rate has gone down over time; however, it nonetheless sometimes exhibits up with expensive consequences. From this chart it is seen that ImAg is an effective surface end if one is assured that the product is not going to be exposed to sulfur throughout shipping or use of the product. Another issue was tarnishing of any uncovered silver after the meeting has been in the area for a period of time.

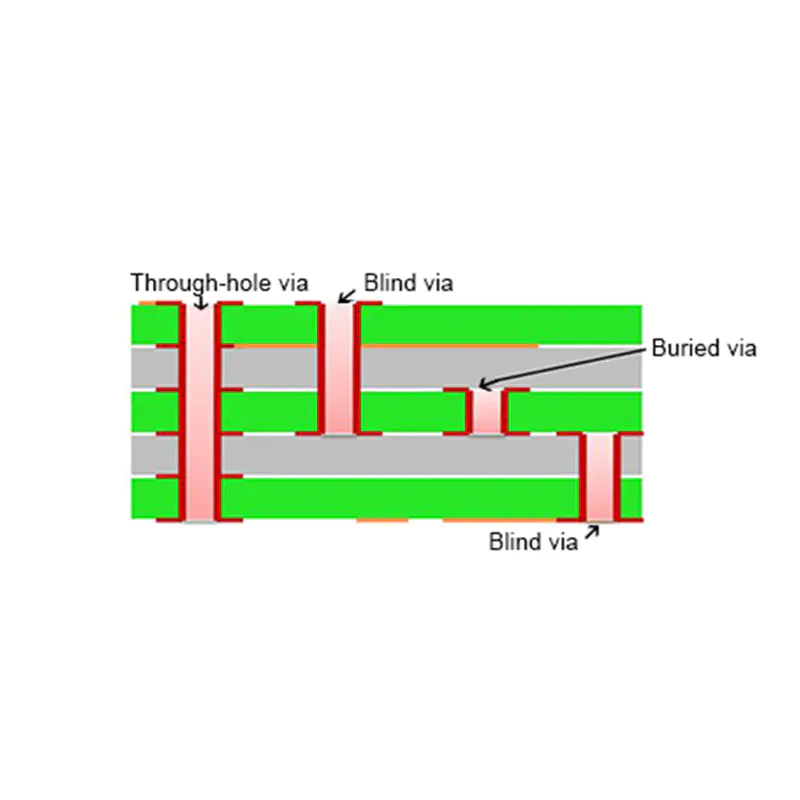

It will have an effect on solder wetting especially hidden joints at SMT thermal pads BTC And at PTH holes these can't positive via X Ray Pl. You can do easy exams for the presence of OSP coating using silver nitrate solutions or you can have sample reworked and recoated with OSP by another provider to verify it's a coating problem.

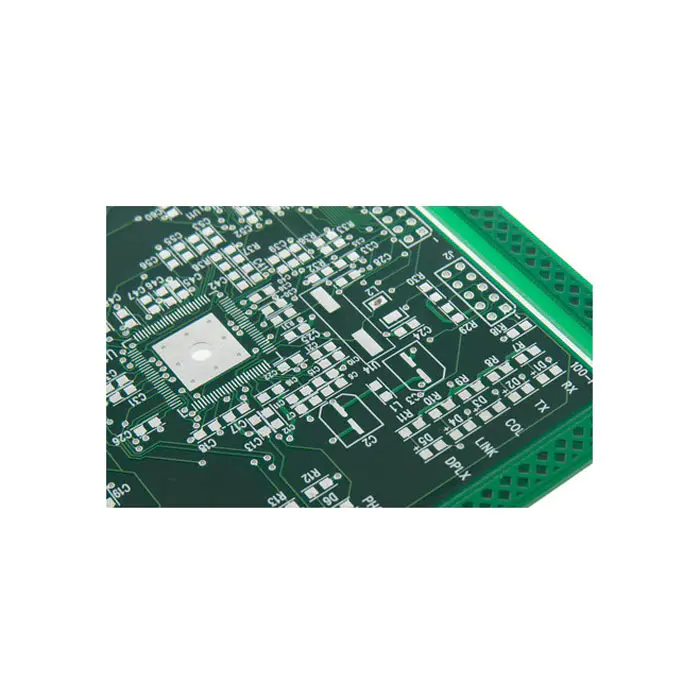

A midrange value finishing that's in style for North America and Europe as a result of RoHS and WEEE regulation. A good various to ENIG if you would like good properties at a lower cost. Although it can be troublesome to test, as beforehand mentioned, it is very nicely suited to fantastic pitches, BGA, and small components because the topography of the coating may be very flat. It also doesn’t demand excessive tools upkeep and is highly repairable.

Surface bondability for chip mounted components using gold and aluminum wire. If you are not already a present buyer of MCL, now is the time to make the swap! For boards larger than 2-layers, we'll subtract $195 off of the entire tooling worth. Immersion Tin (ISn) is applied on to the bottom metallic of a PCB through chemical displacement. After OSP utility, the panels must be dried instantly and all holes have to be blown out to make sure no residual OSP chemistry seeps out when boards are able to be delivered.