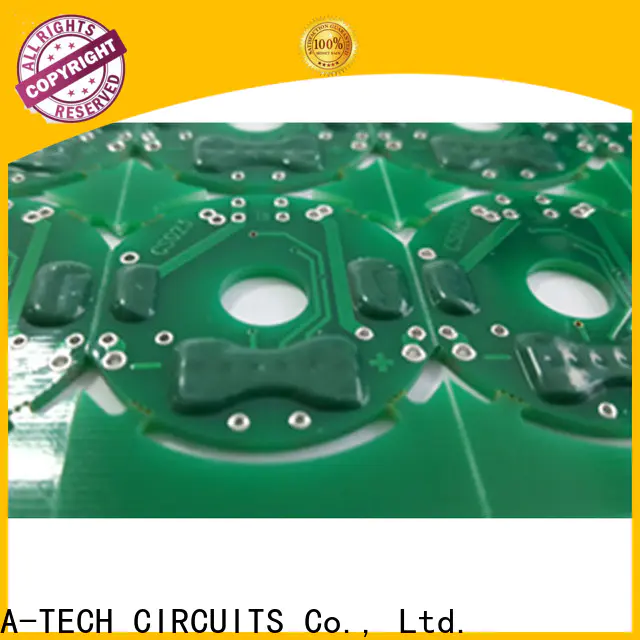

Peelable mask is one kind of temporary soldermask which use to protect some selected board areas during the surface finish or PCB assembly process to keep solder from flowing onto contacts, terminals or plated through holes.

Peelable mask are applied by screen-printing, act as in-process protection and are removed after processing at the assembler. Because the fabricator can apply the mask in any design, they can create one fluid piece which will allow the customer to peel the entire design off in one pull.

Peelable mask provides protection in soldering processes like wave soldering, reflow soldering or hot air solder leveling(HASL). Rebiable, time-saving and cost-saving in their application, they have long surpassed manual masking with heat-resistant tapes.

The benefits of peelable mask

● Cost and time saving process compared to taping

● Protection of plated through holes

● Protection of selected areas on the PCB during various finishing or assembly processes

● Protection of complex structures and shapes by efficient screen-printing

● Overprinting of carbon inks

● Highest temperature acceptance and good peel-ability

● Easily removes and leaves no residue

A-TECH built a large number of printed circuit boards with peelable mask requirements, we use the peelable mask brand of PETERS, which is the highest quality level for this material to ensure that they can be peeled off easily after assembly process without any residue, and we use papers to separate every pieces of board in vacuum package to avoid any contamination on the appearance of PCB.

Copyright © 2025 A-TECH CIRCUITS Co., Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.