Company Advantages1. A-TECH

pcb gold plating will be scrutinized by professional workers for its workmanship. Seaming and Stitching quality will be checked more carefully, especially for the irregular stitch density, crooked stitches, skipped stitches, exposed seam grin, unwanted pleat, and cracked seam.

2. The product has a robust and strong structure. Constructed with quality metal or plastic frame, it is not easy to deform and crack.

3. An evenly painted surface is a light spot of the product. It has been processed under large-scale auto-painting equipment, enabling it to have to good fullness, bright, and smooth surface.

4. The product has become a necessity for many industries. It brings enormous economic benefits by improving productivity and cutting costs.

5. People do not have to worry that their electricity supply capacity is not adequate to run this product. Instead, it helps cut the electricity demands.

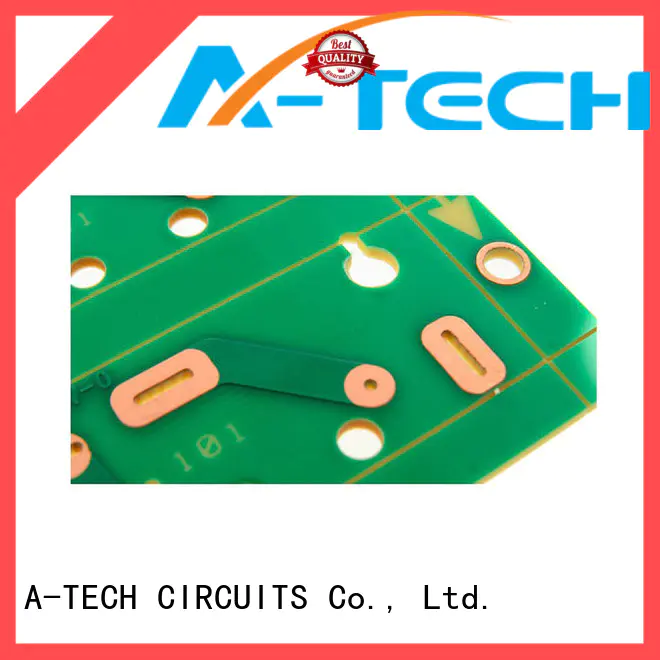

OSP, the full name is Organic Solderability Preservative, it preserves the copper surface from oxidation by applying a very thin protective layer of material over the exposed copper usually using a conveyorized process. It uses a water-based organic compound that selectively bonds to copper and provides an organometallic layer that protects the copper prior to soldering. It’s also extremely green environmentally in comparison with the other common lead free finishes, which Suffer from either being more toxic or substantially higher energy consumption.

The typical thickness of OSP is 0.2 – 0.65um and the shelf life is 6 months. It’s a simple manufacturing process to make OSP, and like HASL finish, the production cost of OSP is lower than most of other surface finishes.

The applications of thick copper PCBs

● Cost effective / Low cost

● Simple process

● Excellent flatness

● Re-workable

● Clean, environmentally friendly process

The disadvantages of OSP

● Short shelf life

● Very sensitive to handling – gloves must be used and scratches avoided

● Short operating window between assembly stages

● Not suitable for multiple soldering processes

● Difficult to inspect or measure thickness

A-TECH own OSP line in house, it’s nowadays mainly used to build single-sided FR4 PCB or aluminum PCB with low cost requirements.

Company Features1. With years of focus on design and production, A-TECH CIRCUITS Co., Ltd. has earned a reputation as a skilled and innovative manufacturer of pcb gold plating .

2. As the need for automation continues to grow, our factory has newly introduced sets of semi-automation and full-automation facilities. This enables us to continually make improvements in quality such as precision and innovation.

3. Efforts are being made for A-TECH CIRCUITS Co., Ltd. to be China's best immersion tin pcb company with great international influence. Check now! A-TECH CIRCUITS Co., Ltd. is prepared to present the best service and immersion gold pcb for every single client. Check now! A-TECH CIRCUITS Co., Ltd. adheres to the plan of going global and aims to become a global brand. A-TECH CIRCUITS Co., Ltd. adheres to the great fantasy of leading the growth of pcb mask business. Check now!