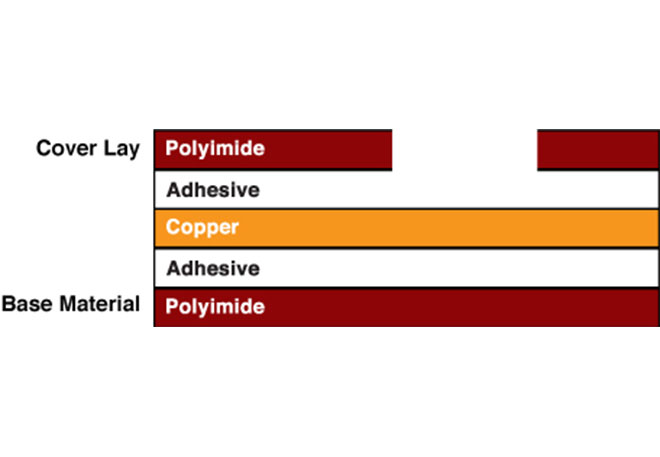

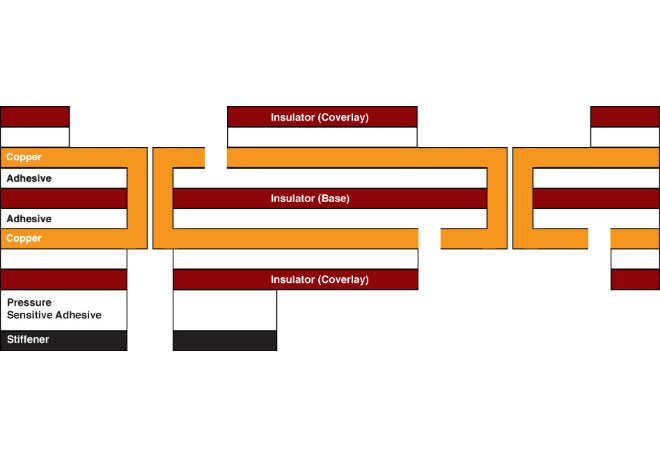

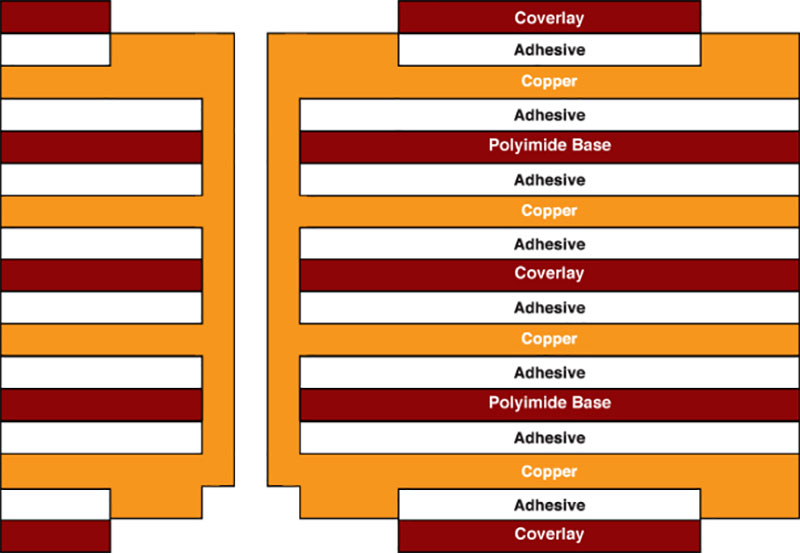

Flexible PCB, which also called Flex PCB, Flexible circuit board or flex circuit, it consists of PI base material, adhesive layer, copper layer, coverlay and sometimes with stiffeners. Flexible PCBs are now being used widely to replace traditional FR4 PCB in various different applications due to the benefits from flex PCB specially. Although more expensive than a normal rigid PCB, the right design in the right application could save weight and time in assembly, coupled with the reliability which makes flexible circuit board a worthwhile consideration.

The benefits of flexible printed circuit boards

● Reduce weight and space

● More flexibility as the name suggests

● Small package size.

● Allows for more compact devices

● Allows the board to bend to its desired applicable shape

● High tensile strength – can be significantly warped/deformed without breakage.

● High Bendiness – up to 360 degrees

● Easier to prepare for harsh environments.

● The use of flexible flat cables(FCC), which can bend without being damaged, and takes up less space than traditional wires.

The applications of flexible PCB

● Communications

● Industrial

● Consumer Electronics

● Aerospace

● Automotive

● Military

● Medical

● Transportation.

With a large number of investments on the facilities of flexible printed circuit board and continuously innovating the flexible circuit board manufacturing technology, A-TECH is able to manufacture flexible PCBs with a great variety of technologies, from simple single sided flex PCB, double sided flex PCB to complex multilayer flexible PCB, and support prototype FPC with laser cutting & flying probe test to mass production with toolings.

| General specification for flexible PCB in A-TECH | |

| Layer Count | 1-6 layers |

| Board thickness | 0.05-0.3mm |

| Base polyimide film thickness | 0.5 mil (12.5µ), 1 mil (25µ), 2 mils (50µ). |

| Copper thickness | 1/3oz (12µ), 1/2oz (18µ), 1oz (35µ), 2oz (70µ) |

| Stiffeners | Polyimide, FR4, Metal |

| Min trace width/spacing | 3/3mil(0.075/0.075mm) |

| Min drill size | 0.2mm |

| Surface treatment | Immersion Gold/Tin, Gold/Tin Plating, OSP |

Copyright © 2025 A-TECH CIRCUITS Co., Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.