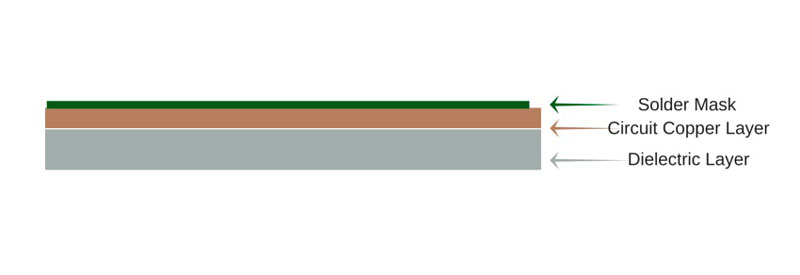

Single sided PCB is the most cheap and simple type of printed circuit boards, it has only one layer of conductive copper layer with NPTH(non-plated through hole), but no PTH(plated through hole) or via holes. This type of PCB can be used for both through hole and surface mount components.

Single sided printed circuit boards are easily designed and best suited for low density designs, they serve as the most cost effective platform in the industry and they can be manufactured with short processes and lead time.

The benefits of single sided PCBs

● Lower cost, especially for high volume orders

● Lower probability of manufacturing issues

● Ideal for simple low-density designs

● Popular, common, and easily understood by most PCB manufacturers

● Less manufacturing processes with faster lead time

A-TECH CIRCUITS manufactured single sided PCBs for decade, with our high efficiency in production and excellent production yield rate, we’re capable to offer very low price and quick lead time to benefit customers. The following is the basic specifications we fabricated for single sided circuit boards.

| General Specification for single sided PCB in A-TECH | |

| Layer Count | 1 Layer |

| Material Available | CEM1, CEM3, FR4, High Tg FR4, AL base, PI, Teflon, Taconic, Arlon, Rogers. |

| Max board size | 510*1500mm |

| Board thickness | 0.4-3.2mm |

| Finished copper thickness | 1-3oz |

| Min trace width/spacing | 4/4mil |

| Min hole size | 0.2mm |

| Colour of Solder Mask | Green, Blue, White, Black, Yellow, Red. |

| Colour of Silkscreen | White, Black, Yellow. |

| Surface treatment | HASL, HAL(Lead free), OSP, Gold Plating, Immersion Gold/Tin/Silver, carbon. |

Copyright © 2025 A-TECH CIRCUITS Co., Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.