Company Advantages1. The materials A-TECH pcb production uses have been well selected and strictly tested. A smooth part is added on its PTH line to reduce the roughness of through hole

2. Only qualified pcb production can be packed in A-TECH CIRCUITS Co., Ltd.. It has passed AOI which ensures there will be no errors or welding defects

3. The quality test is conducted by professional team and the third parties as well. It is 100% produced in accordance with IPC-6012 & IPC-A-600F standards

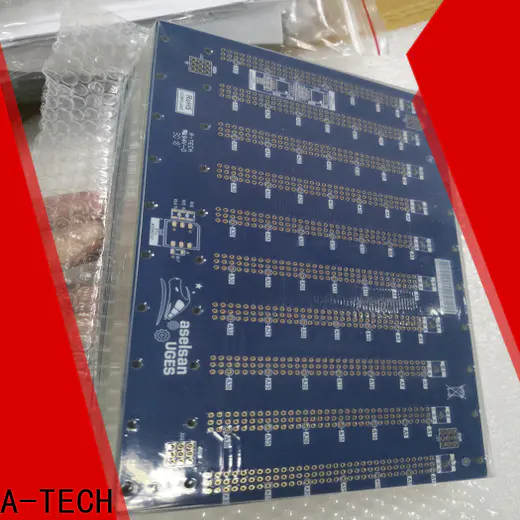

4 layers PCB with 2.64mm board thickness, ShengYi S1000-2 material with TG170, inner copper 2oz and outer copper 3oz, immersion gold finish with min gold thickness 2U”, Blue solder mask, White Silkscreen. There are press fit hole design with tolerance +/-0.05mm(2mil).

Company Features1. A-TECH CIRCUITS Co., Ltd. is recognized as an expertise in the pcb production industry. Our technical team provide strong support to our efforts to tackle technical difficulties in rigid flex pcb production.

2. Advanced technology of has been applied to the production of

circuit board assembly .

3. As a high-tech enterprise, A-TECH CIRCUITS Co., Ltd. has full capability in technology innovation. For these years, A-TECH CIRCUITS Co., Ltd. has take as its life. Call!