Company Advantages1. The fibers of A-TECH

immersion silver pcb finish will be rigorously tested before used. The fibers are checked using various methods such as combustion, dissolution, staining, or infrared spectrometry method.

2. The part that directly contacts with water will not contaminate the water source. The parts are made of food-grade materials which will not release any toxic substances.

3. No defects can be found on this product, namely overall product failure or reduced usability of the product that prevents it from being placed on the market which can include open seams, holes or broken stitches.

4. A-TECH PCB is favored by customers both at home and abroad.

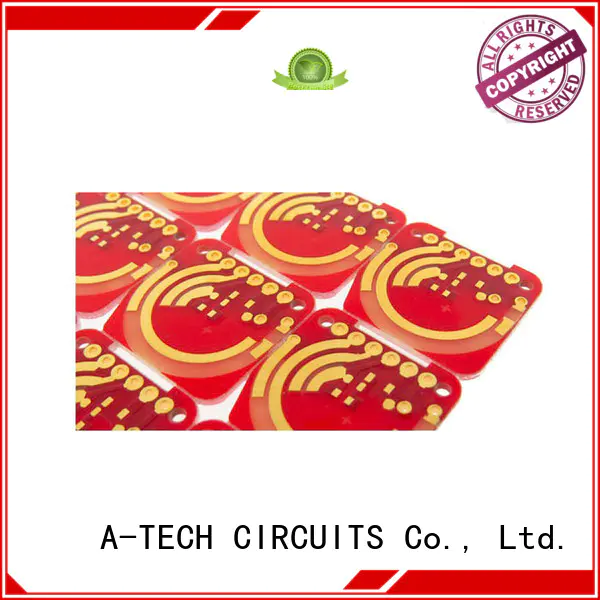

5. As a major supplier for pcb mask, A-TECH CIRCUITS Co., Ltd. has conducted strict quality tests before shipment.

Hard gold plated, the full name is Electrolytic Nickel Electrolytic Gold. The most common application of hard gold plated is edge connectors(gold fingers), and it may also be plated over the entire circuit boards.

Hard Electrolytic gold consists of a layer of gold plated over a barrier coat of nickel. Hard gold is extremely durable, so it is most commonly applied to high-wear areas such as gold fingers and keypads.

Hard gold is not generally applied to solderable areas, because of its high cost and its relatively poor solderability. The maximum thickness that IPC considers to be solderable is 17.8U”, so if this type of gold must be used on surfaces to be soldered, the recommended nominal thickness should be about 5-10U”.

The advantages of hard gold plated

● Hard, Durable surface

● RoHS Compliant

● Long Shelf life

● Excellent for high-wear products

The disadvantages of hard gold plated

● Additional high cost

● Extra complicated manufacturing process

● Etching undercut can lead to slivering/flaking

● Finish does not fully encapsulate trace sidewalls, except in gold finger areas

A-TECH is capable of using hard gold plated on both of gold fingers and the entire PCB, the typical thickness of hard gold plated for gold fingers can be 0.1 – 3.0um, and the typical thickness of hard gold plated on entire board is 0.1 – 1.27um.

Company Features1. A-TECH CIRCUITS Co., Ltd. provides high quality pcb mask of various types for you.

2. Quality speaks louder than number in A-TECH CIRCUITS Co., Ltd..

3. We offer a culture of empowerment. All of our employees are challenged to be creative, to take risks and to constantly find better ways to do things, so that we can continue to delight our customers and grow our business. Our company has embarked on a journey promoting environment-friendly and sustainability initiatives. We are involved in various projects including renewable energy management and waste disposal management. We have set up a green team to promote sustainable development. They research new sustainability trends and initiatives, monitor progress in production, so as to guarantee continuous and ongoing improvement in sustainability. Our company will actively foster sustainable practices. We have made progress in reducing waste gases, polluted water, and conserving resources.