HASL, the full name is Hot Air Solder Leveling, it’s one of the traditional surface finish on printed circuit boards with long successful history.

To make the HASL finish, the circuit boards will be submersed in molten solder(Tin/Lead). This solder will cover all the exposed copper surfaces. Upon retraction from the solder, high pressure hot air is blown over the surface through air knives, this levels the solder deposit and removes the excess solder from the surface of printed circuit boards.

HASL (Tin/Lead) surface finish is not RoHS Compliant, so it can be only available where RoHS exemption is permitted. The typical thickness of HASL is 1-40um, and the shelf life can reach to 12 months.

The advantages of HASL surface finish

● Excellent solderability / wettability

● Good reflow properties

● Low cost in manufacturing

● Large processing window is allowed

● Multiple thermal excursions

● Can be widely used

The disadvantages of HASL surface finish

● Uneven surface

● Not suitable for PCBs with fine pitch

● Thermal shock

● Not RoHS Compliant

● Solder bridge

● Plugged or Reduced plated through holes

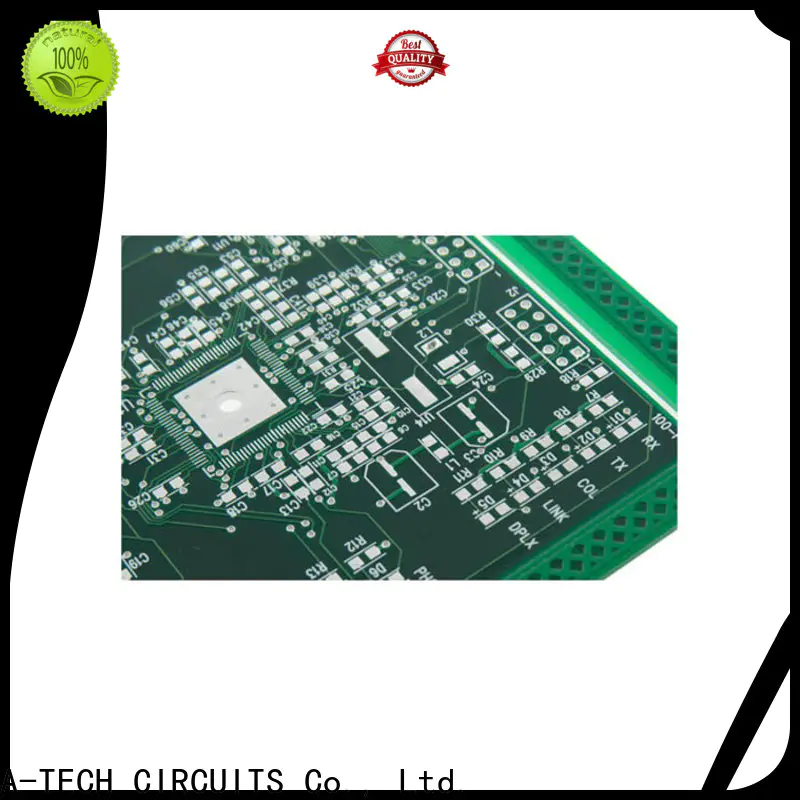

A-TECH have HASL surface finish in house, it’s mainly used to build single sided or double sided PCBs with high solderability requirements but low manufacturing cost and without RoHS Compliant requirement.

Copyright © 2025 A-TECH CIRCUITS Co., Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.