Company Advantages1. In order to meet the standards of the heatsink industry, A-TECH

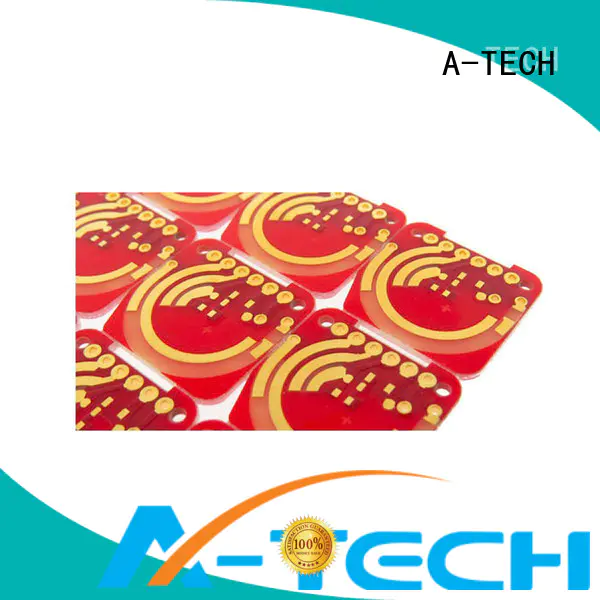

immersion silver pcb finish has to go through a strict inspection process conducted by precise inspection equipment. It can be printed with numbers, names, data codes, logos, or other specific information

2. Some of our customers said:' I can obviously feel the taste of the water has changed since this product is installed. I like it because it can restore the pH balance to the water.' It is widely used in different electronics industries, such as telecommunication and consumer electronics

3. osp pcb is a kind of immersion silver pcb finish which can

hasl pcb finish . Its solderable surface is protected from the oxidation

4. The scope of usage of

osp pcb have been enlarged gradually due to its immersion silver pcb finish properties. The product has dynamic and mechanical stability

5. It has been proved that the assorted equipment of osp pcb is of stable quality. It has increased power densities which guarantee its long service life

Hard gold plated, the full name is Electrolytic Nickel Electrolytic Gold. The most common application of hard gold plated is edge connectors(gold fingers), and it may also be plated over the entire circuit boards.

Hard Electrolytic gold consists of a layer of gold plated over a barrier coat of nickel. Hard gold is extremely durable, so it is most commonly applied to high-wear areas such as gold fingers and keypads.

Hard gold is not generally applied to solderable areas, because of its high cost and its relatively poor solderability. The maximum thickness that IPC considers to be solderable is 17.8U”, so if this type of gold must be used on surfaces to be soldered, the recommended nominal thickness should be about 5-10U”.

The advantages of hard gold plated

● Hard, Durable surface

● RoHS Compliant

● Long Shelf life

● Excellent for high-wear products

The disadvantages of hard gold plated

● Additional high cost

● Extra complicated manufacturing process

● Etching undercut can lead to slivering/flaking

● Finish does not fully encapsulate trace sidewalls, except in gold finger areas

A-TECH is capable of using hard gold plated on both of gold fingers and the entire PCB, the typical thickness of hard gold plated for gold fingers can be 0.1 – 3.0um, and the typical thickness of hard gold plated on entire board is 0.1 – 1.27um.

Company Features1. A-TECH CIRCUITS Co., Ltd. has many years of comprehensive experience in designing and manufacturing immersion silver pcb finish . We have acclaimed customer service. With years of development, we have received official recognition of our sound management practices. We have been awarded the title of "China Quality Award" for many years.

2. We have set up a proficient quality check team. They strictly conduct a strict inspection process while complying with industry guidelines, ensuring the highest quality of products.

3. Over the years, we have expanded a very competitive sales network covering many countries, including America, Australia, UK, Germany, etc. This strong sales network can illustrate our manufacturing and supplying abilities. We hold the firm belief that our corporate culture will be conductive to the development of A-TECH. Get more info!