Company Advantages1. The quality control of A-TECH is conducted rigorously. It is tested in terms of its air circulation, surface treatment, as well as the most important part, thermal dissipation performance. The product has dynamic and mechanical stability

2. Through fully mature quality test, the quality of our flexible printed circuit board can be guaranteed. With a solder mask, it enjoys a good electrical insulation property

3. This product has precision specifications. All of its mechanical components are manufactured from a wide range of special CNC machines with the required precision. Its robust structure allows it to be used in harsh environments

4. The ability to stay cool and dry is one of the critical features of this product. It allows the moisture to evaporate very fast, instead of leaving it inside. It has passed AOI which ensures there will be no errors or welding defects

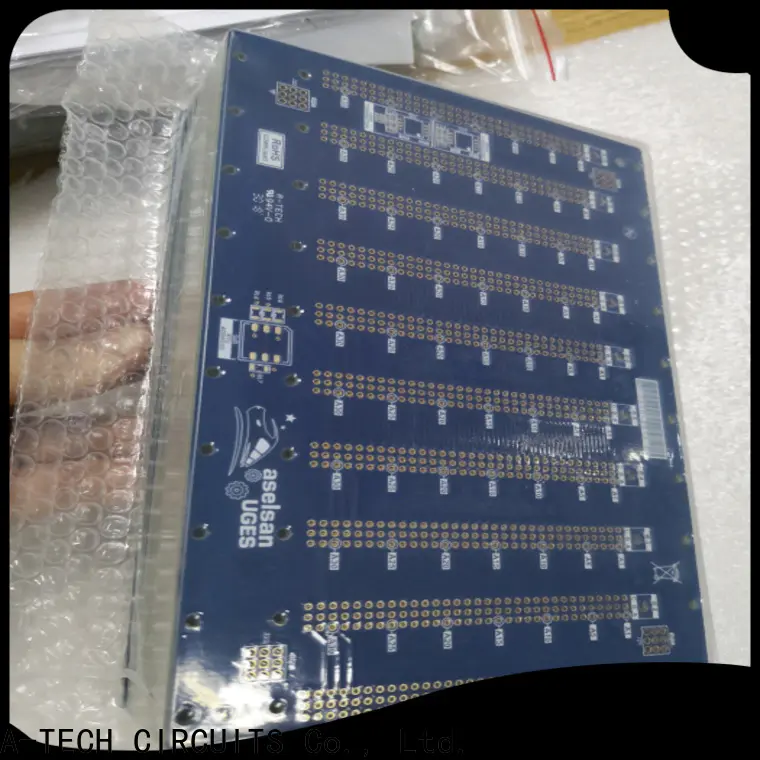

4 layers PCB with 2.64mm board thickness, ShengYi S1000-2 material with TG170, inner copper 2oz and outer copper 3oz, immersion gold finish with min gold thickness 2U”, Blue solder mask, White Silkscreen. There are press fit hole design with tolerance +/-0.05mm(2mil).

Company Features1. A-TECH CIRCUITS Co., Ltd. enjoys increasing popularity both at home and abroad. The ability to produce makes us be thought as the leader in the industry. Our technical team in A-TECH CIRCUITS Co., Ltd. are asked to update their professional knowledge when necessary.

2. By giving play to strong points of and , flexible printed circuit board can maximize the value of it.

3. The quality of pcb service is strictly controlled from . Our firm bears societal responsibilities. By simplified procedures using new, advanced materials, our associates can reduce raw material use and completely use the necessary resources, which leads to renewable eco-efficient source usage.