Company Advantages1. In terms of surface finishes, A-TECH provide all possible options. The surface treatment is available in a variety of ways. It can be manufactured with a customized thickness

2. Free samples of our pcb fabrication can be provided for testing first before you place big order. The product is certified under UL(E357001) and RoHS

3. The product is efficient in thermal dissipation. The material used in it features excellent heat conducting and it is thermally efficient. It is characterized by high thermal conductivity and good heat dissipation

4. Efficient heat transfer is one of its biggest selling points. The materials' thermal conductivity is high and has relations to their heat dissipation efficiency. It has low water absorptivity in the damp environment

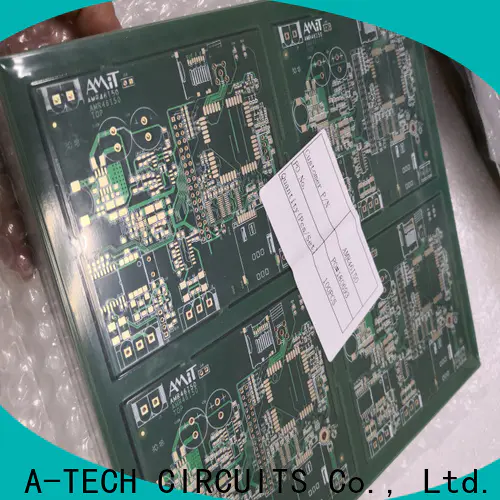

A-TECH manufacture double-sided PCB mainly with kingboard 6160 material, from normal TG130-140, middle TG150 to high TG with TG170, it meets UL, ISO and RoHS certificate. Double-sided PCB is one of the major products in A-TECH with great advantage on price and quality, the monthly output can be 15000 square meters.

Company Features1. Over the past years, A-TECH CIRCUITS Co., Ltd. has been focusing on the development, production, and marketing of . We have been widely accepted in China.

2. We have an experienced research and development team. They embrace a wealth of expertise and industry know-how, which enables them to provide technical services and to help clients quickly and efficiently to complete product development.

3. In future, A-TECH CIRCUITS Co., Ltd. will continue to expand strenuously the pcb fabrication services. Get an offer!