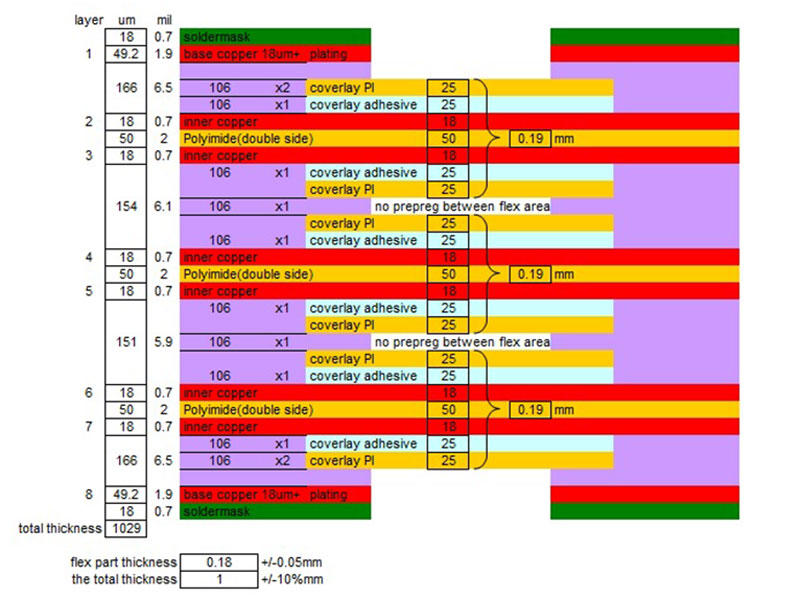

Rigid flex PCB, as the name suggests, it’s combined with rigid PCB and flex PCB, and the rigid circuits are connected with single or multiple flex circuits through plated through holes. Coverlay’s are applied to the flexible copper conductor and liquid photo imagable solder resist applied to the rigid PCB areas.

Rigid flex PCB is different with the case of flex PCB with FR4 stiffeners, basically no any conductors or plated through holes(PTH) on FR4 stiffener but only be used with the purpose of increasing strength for specified areas, for rigid part of rigid flex PCB, there are conductive circuit patterns and plated through holes extend through both rigid and flex layers.

The benefits of rigid flex PCBs

● Dynamic and mechanical stability

● 3-dimensional freedom of design

● Simplified installation

● Space saving

● Maintenance of uniform electrical characteristics

The application of rigid flex PCBs

● Consumer Electronics

● Industrial Controls

● Medical

● Military

● Optoelectronics

● Semiconductor

● Testing & Measurements

Stackup of 8 layers Rigid-flex PCB

With several years’ experience in manufacturing rigid flex PCBs and continuously investing to use state-of-the-art equipments, A-TECH own mature technology and excellent quality control system to ensure high level quality of products. Currently we’re able to fabricate various rigid flex PCB from double sided to multi layers with complex constructions.

| General specification for rigid flex PCB in A-TECH | |

| Layer Count | 2-16 layers |

| Board thickness | 0.6-3.0mm |

| Base polyimide film thickness | 0.5 mil (12.5µ), 1 mil (25µ), 2 mils (50µ). |

| Copper thickness | 1/3oz (12µ), 1/2oz (18µ), 1oz (35µ), 2oz (70µ) |

| Copper thickness(rigid part) | 1/2oz (18µ), 1oz (35µ), 2oz (70µ), 3oz (105µ) |

| Stiffeners | Polyimide, FR4, FR4(High Tg) |

| Min trace width/spacing | 3/3mil(0.075/0.075mm) |

| Min drill size | 0.2mm |

| Surface treatment | Immersion Gold/Tin, Gold/Tin Plating, OSP |

Copyright © 2025 A-TECH CIRCUITS Co., Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.