a printed circuit board (pcb) assembly service can lower costs and improve quality

Assembly is one of the manufacturing processes required for the production of consumer electronics.

In the past, consumer electronics OEMs (OEM)

Assemble pcb at home.

However, due to the rapid development of surface installation technology and the innovation of manufacturing processes and equipment, PCB assembly is now often outsourced to contract electronics manufacturers specializing in PCB assembly.

There are decisive advantages in using PCB assembly services. They include:1.

Reduce capital investment.

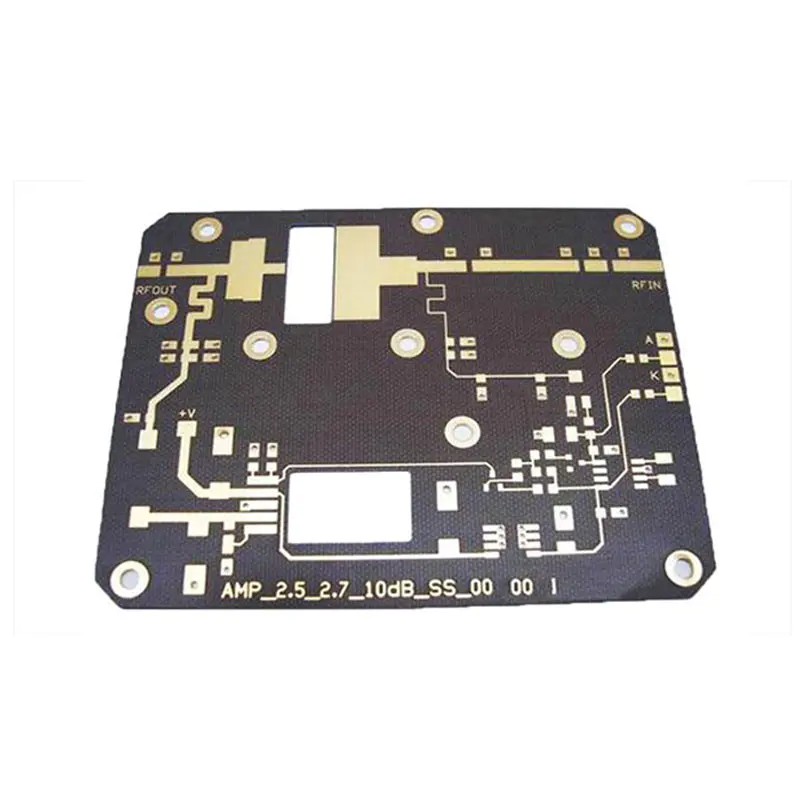

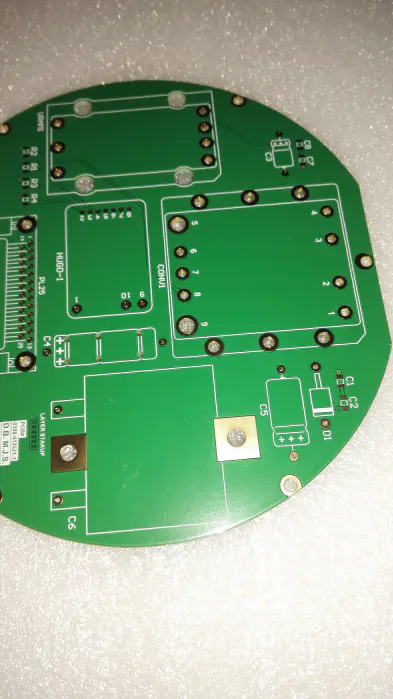

Assembled circuit board-

The house requires a substantial capital investment in manufacturing facilities, lines and machinery, and in the recruitment and training of qualified personnel.

So this could be a long return --on-investment (ROI).

The use of outsourcing services makes financial and economic sense. 2.

Cost per unit benefit.

Consumer electronics OEMs can benefit from a \"economies of scale\" by leveraging the capital investment of PCB services in facilities, equipment and personnel to reduce unit costs \", this can make them more competitive in the market. 3.

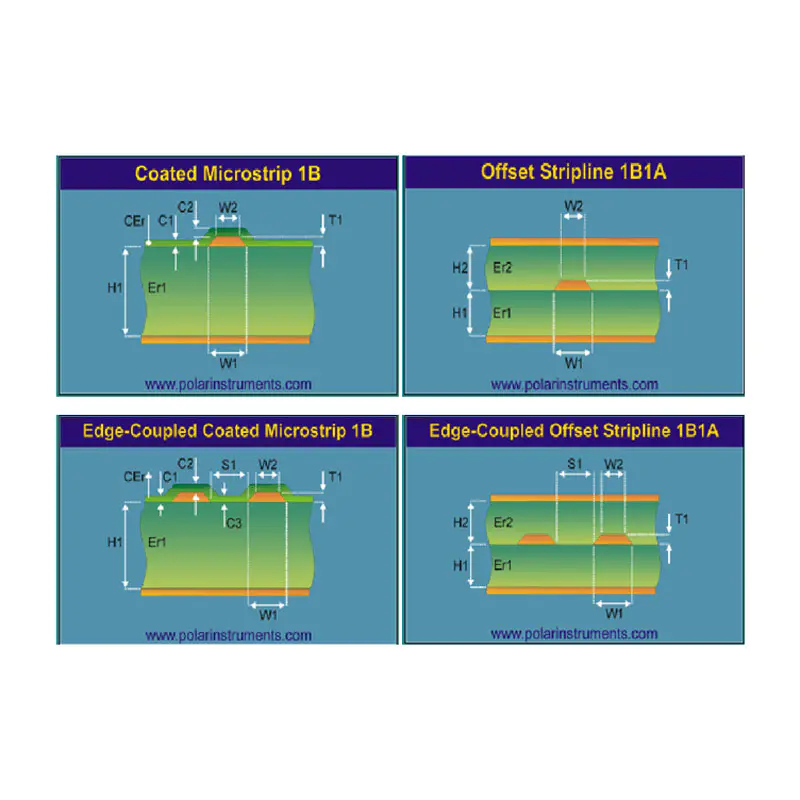

Product design improvements.

PCB services sometimes include electronic design services as part of their assembly costs.

These design services can validate the electronic design and advise on PCB improvements that will translate into high quality products at a lower cost. 4.

The value of rich experience.

Outsourced PCB services have extensive experience in quality

Even within a tight deadline, PCBs should be produced at the lowest possible price.

This value cannot be underestimated. 5.

Quality Assurance.

In today\'s highly competitive market, quality assurance is essential in order to control unexpected costs and maintain customer satisfaction.

Not all consumer electronics manufacturers have quality systems and resources and test equipment that guarantee the quality of their pcb.

Instead, PCB manufacturers use a variety of quality systems and procedures to ensure quality assurance.

In addition, they have a business relationship to purchase high-quality electronic components.

This is critical because to trust the final product, the components used to produce the product must be trusted.

Today\'s customers use the Internet to study not only the products and services of consumer electronics companies, but also their business reputation.

If a consumer electronics company is known for producing products of low quality, this may cause irreversible damage to its business reputation.

This is critical to what PCB services can do for you: reduce costs and guarantee the quality of your products to enhance your business reputation.

It makes sense to work with contract electronics manufacturers to produce pcb.