5 Types Of Pcb Surface Finishing

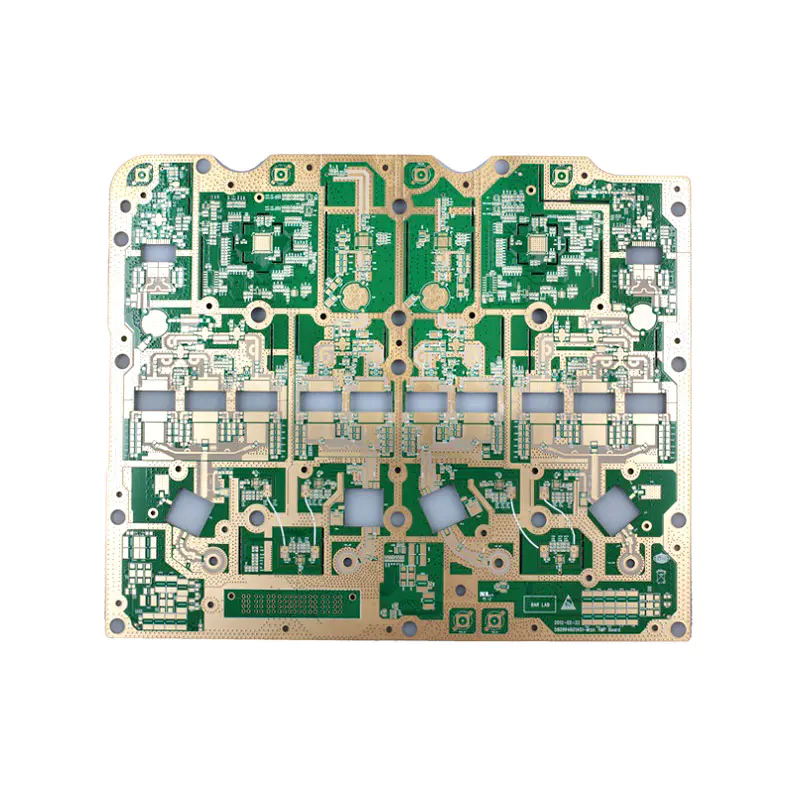

Normally the inside surfaces of the holes have copper layer so that they electrically join the layers of the board. Although most PCB boards are manufacturing utilizing photographic processing, other methods are additionally obtainable. The machine is then managed to mill away the copper in these areas where the copper just isn't required.

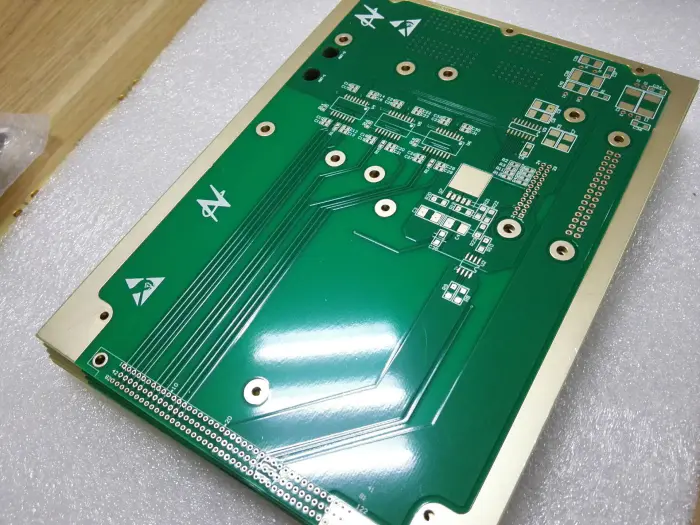

17 Unless the printed circuit boards are going for use instantly, they are individually packaged in protective plastic baggage for storage or shipping. 14 Individual boards move by way of several machines which place the electronic elements of their proper location within the circuit.

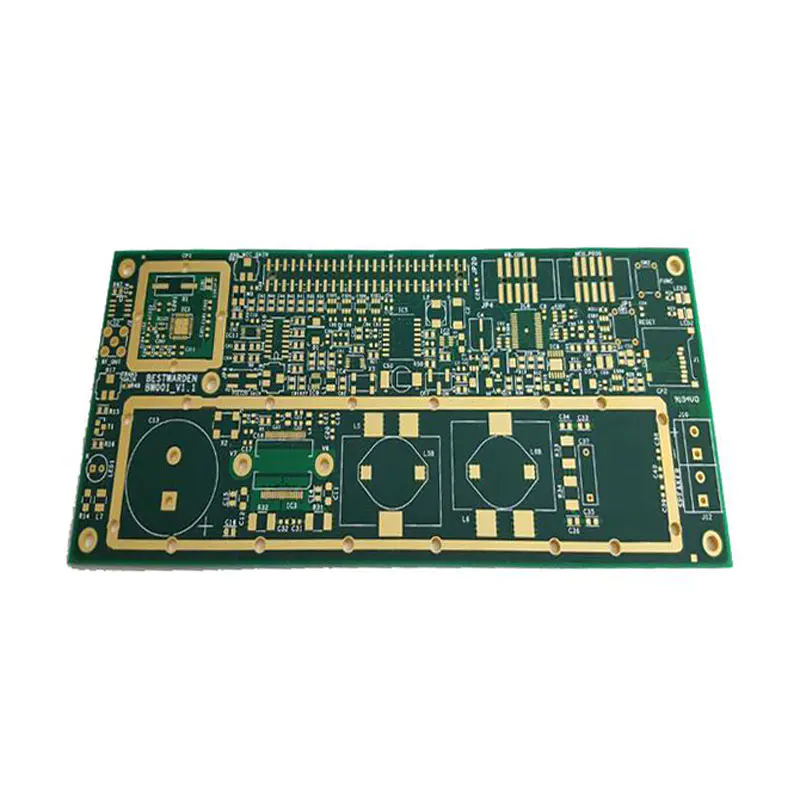

Usually, the elements of OSP are alkylbenzimidazole, natural acid, cupric chloride and deionized water,etc. Our numerous surface end choices are listed within the table beneath, together with some fundamental info regarding every finish. For Circumstance#1, in the process of soldering, flux is able to serving to eliminating oxidations so that soldering performance will not be influenced.

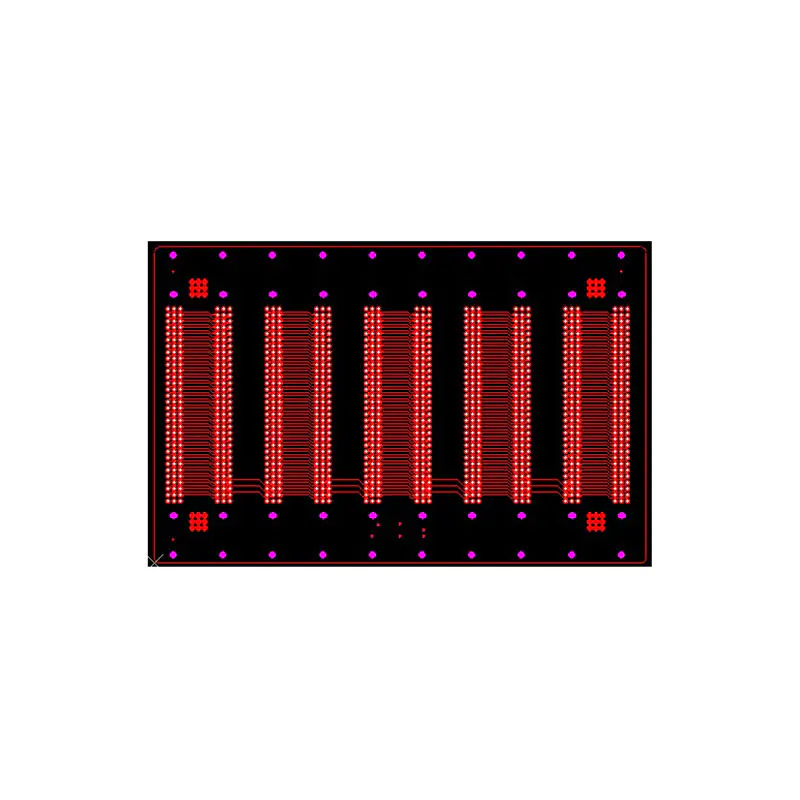

On the contrary, Circumstance#2 occurs as a result of OSP integrity has been destroyed so that flux isn’t able to eliminating oxidations, which will greatly lower the soldering performance. The operate of 'Clean' is to scrub off the natural contaminants corresponding to oil, finger prints, oxidation movie and so on. so as to get copper foil surface stay clean and bright, which is the basic demand. This step plays quite an important function in preservatives build quality. Bad cleaning will tend to cause uneven thickness of preservatives build. In order to ensure the high quality of finished OSP film, on the one hand, focus of cleaning solution must be managed within a regular range through chemical laboratory evaluation.

On the other hand, cleansing effect is suggested to be checked as often as potential and once the effect would not attain the usual, cleaning answer ought to be immediately replaced. In terms of film thickness, movie made through benzotriazoles is skinny whereas that by way of imidazoles is comparatively thick. The differentiation on thickness will deliver distinct impression to impact of board end which shall be discussed within the later a part of this text. PCB designers today are challenged to create reliable boards that perform more and more complicated capabilities whereas controlling prices and shrinking in dimension.

OSP only react with the bare copper to kind non-sticky, skinny and uniform protective film, which implies it will price lower than different floor treatment chemical substances. OSP is the abbreviation of Organic Solderability Preservative that has earned nice reputation in PCB business.

The management is obviously automated and driven from files generated by the PCB design software. This type of PCB manufacture isn't suitable for big amount however it is a perfect choice in lots of cases the place very small portions of a PCB prototype portions are needed.

With the naked PCB boards chosen and obtainable the next step is to create the required tracks on the board and remove the unwanted copper. The manufacture of the PCBs is often achieved using a chemical etching course of.

This is particularly important in applications such as smartphones, drones, and different functions where weight is a critical consideration in the PCB traits. When a PCB is soldered it's essential to hold the areas that are not to be soldered protected by a layer of what is termed solder resist. The addition of this layer helps forestall unwanted quick circuits on the PCB boards attributable to the solder. The solder resist normally consists of a polymer layer and protects the board from solder and other contaminants.